In the dynamic world of pharmaceutical manufacturing, ensuring the integrity of every bottle is critical to maintaining product safety and efficacy. Visual inspectors play a pivotal role in this process, leveraging their expertise and specialized equipment to scrutinize bottles for defects and irregularities. In this article, we explore the significance of visual inspectors in bottle quality control and the technologies they rely on to uphold industry standards.

The Importance of Bottle Inspection in Pharmaceutical Manufacturing

Bottle inspection is a cornerstone of pharmaceutical quality control, serving as the first line of defense against potential defects and contaminants. From glass vials to plastic containers, every bottle must undergo rigorous scrutiny to ensure that it meets the highest standards of quality and safety. Visual inspectors play a crucial role in this process, meticulously examining each bottle for imperfections that could compromise product integrity and patient health.

Meet the Visual Inspector: Guardians of Bottle Quality

Visual inspectors are highly trained professionals tasked with the important responsibility of evaluating bottles for defects and inconsistencies. Armed with keen eyesight and specialized training, these inspectors meticulously examine each bottle, looking for issues such as cracks, chips, and foreign particles. By identifying potential problems early in the manufacturing process, visual inspectors help prevent defective bottles from reaching consumers, safeguarding both the reputation of pharmaceutical companies and the well-being of patients.

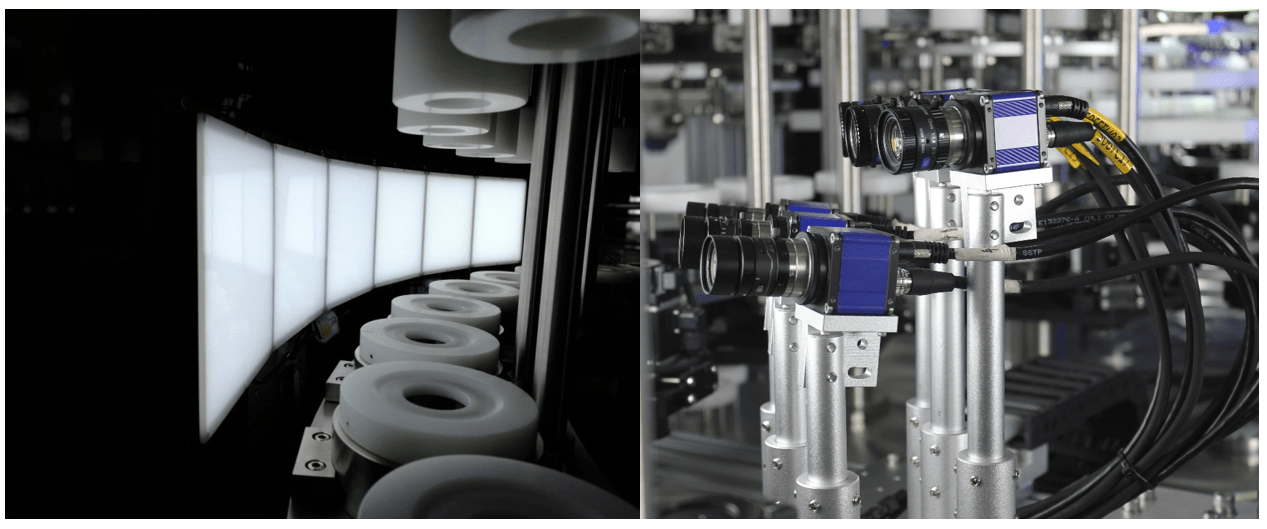

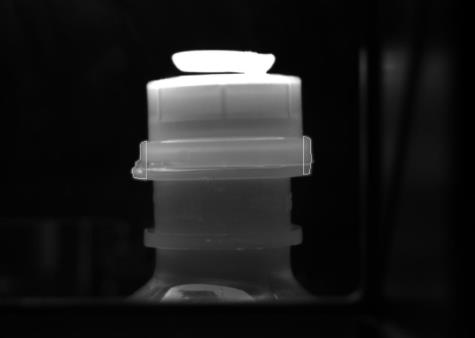

Bottle Inspection Machines: Enhancing Efficiency and Accuracy

To meet the demands of modern pharmaceutical manufacturing, visual inspectors rely on advanced bottle inspection machines equipped with cutting-edge technology. These machines use a variety of techniques, including optical imaging and laser scanning, to detect defects with unparalleled accuracy and efficiency. By automating the inspection process, these machines not only reduce the risk of human error but also enable inspectors to analyze a larger volume of bottles in a shorter amount of time, thereby improving overall productivity and throughput.

Choosing the Right Bottle Inspection Equipment

Selecting the right bottle inspection equipment is essential for ensuring the success of quality control processes in pharmaceutical manufacturing. From compact tabletop systems to high-speed production line machines, there are a variety of options available to suit different production environments and requirements. Factors to consider when choosing bottle inspection equipment include throughput capacity, sensitivity to defects, and compatibility with existing manufacturing infrastructure. By investing in the appropriate equipment, pharmaceutical companies can enhance their ability to maintain product quality and compliance with regulatory standards.

Implementing a Comprehensive Bottle Inspection System

A comprehensive bottle inspection system encompasses not only state-of-the-art equipment but also robust processes and procedures designed to optimize the effectiveness of quality control efforts. This includes establishing clear inspection criteria, training visual inspectors to recognize and classify different types of defects, and implementing regular maintenance and calibration schedules for inspection equipment. By taking a proactive approach to bottle inspection, pharmaceutical manufacturers can minimize the risk of product recalls, regulatory sanctions, and damage to brand reputation.

The Future of Bottle Inspection: Innovations and Trends

As technology continues to evolve, the future of bottle inspection in pharmaceutical manufacturing looks increasingly promising. Emerging innovations, such as artificial intelligence and machine learning, have the potential to further enhance the capabilities of bottle inspection machines, enabling them to detect even the most subtle defects with greater speed and accuracy. Additionally, advancements in robotics and automation are expected to streamline the inspection process further, reducing the need for manual intervention and increasing overall efficiency.

Conclusion:

In conclusion, visual inspectors play a vital role in ensuring the quality and safety of bottles used in pharmaceutical manufacturing. By leveraging advanced inspection equipment and implementing comprehensive quality control systems, pharmaceutical companies can minimize the risk of defects and contaminants, thereby protecting both patients and their own reputation. As technology continues to advance, the role of visual inspectors will remain essential in upholding industry standards and ensuring the integrity of pharmaceutical products.

https://sunchoitrading.cn/inspection-machine/: Ensuring Pharmaceutical Safety: The Role of Visual Inspectors for Bottle Quality Control