In pharmaceutical manufacturing, precision and accuracy are paramount. As the industry continues to push the boundaries of innovation, image processing machines and machine learning are emerging as indispensable tools for ensuring product quality and safety. In this article, we delve into the significance of these technologies and their transformative impact on pharmaceutical inspection processes.

Unlocking Precision: The Power of Image Processing Machines

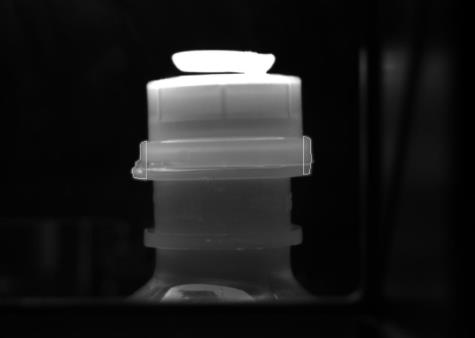

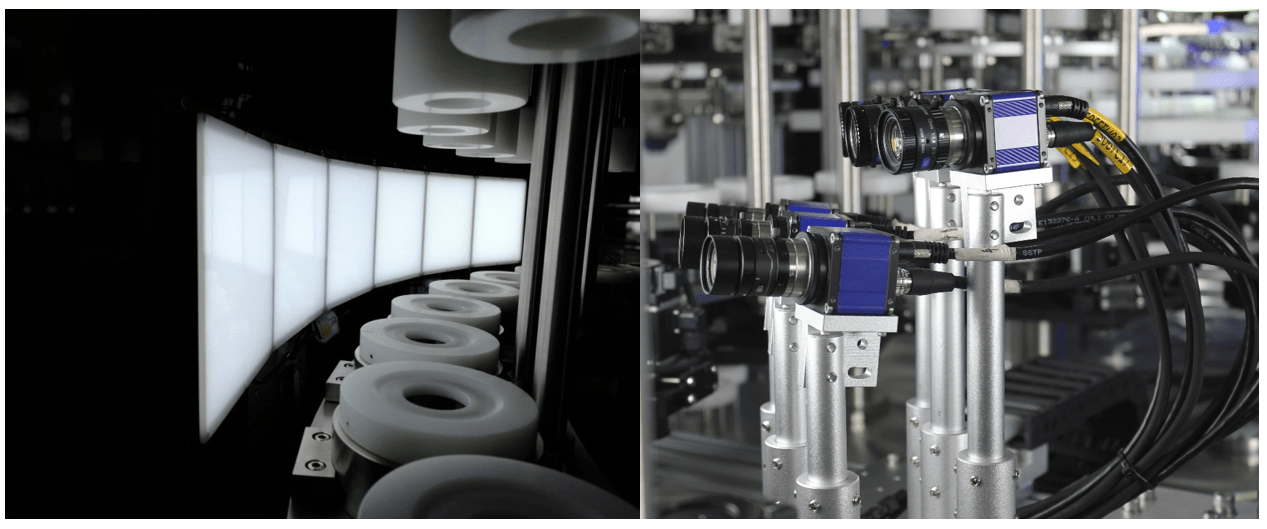

Image processing machines represent a quantum leap in pharmaceutical quality control, leveraging advanced algorithms and computational techniques to analyze and interpret visual data with unparalleled precision. From identifying microscopic defects to detecting subtle variations in product appearance, these machines leave no stone unturned in scrutinizing every aspect of pharmaceutical products, thereby safeguarding consumer safety and upholding industry standards.

Harnessing Intelligence: Machine Learning in Inspection

Machine learning holds the key to unlocking new frontiers in pharmaceutical inspection, empowering systems to learn from data, adapt to changing conditions, and continuously improve performance over time. By training algorithms on vast datasets of images and inspection results, machine learning algorithms can identify complex patterns, predict potential defects, and optimize inspection processes with remarkable accuracy and efficiency, thereby revolutionizing the way pharmaceutical manufacturers approach quality control.

Defect Identification Machines: Redefining Quality Assurance

Defect identification machines serve as vigilant sentinels, meticulously scanning pharmaceutical products for any deviations from predefined quality standards. Powered by image processing algorithms and machine learning models, these advanced systems can detect even the most elusive defects, ranging from cracks in tablets to irregularities in packaging, with unmatched sensitivity and reliability. By flagging potential issues in real-time, defect identification machines enable manufacturers to take proactive measures, mitigate risks, and uphold the integrity of their products.

Precision Redefined: The Quest for Visual Inspection Accuracy

Visual inspection accuracy lies at the heart of pharmaceutical quality control, ensuring that every product meets the highest standards of safety and efficacy. With the advent of image processing machines and machine learning algorithms, manufacturers can achieve unprecedented levels of accuracy in visual inspection, surpassing the capabilities of human inspectors and reducing the risk of false positives and false negatives. By combining the power of automation with the insights of artificial intelligence, visual inspection accuracy reaches new heights, setting new benchmarks for excellence in pharmaceutical manufacturing.

Empowering Professionals: The Rise of Visual Inspection Specialists:

In an era defined by technological innovation, visual inspection professionals play a crucial role in harnessing the full potential of image processing machines and machine learning algorithms. Equipped with specialized knowledge and expertise, these professionals serve as the frontline defenders of pharmaceutical quality, overseeing inspection processes, interpreting results, and ensuring compliance with regulatory requirements. By partnering with visual inspection specialists, pharmaceutical manufacturers can leverage their insights and experience to optimize inspection workflows, maximize efficiency, and maintain the highest standards of product quality.

The Role of Inspection Technicians in Ensuring Product Integrity

Inspection technicians are the unsung heroes behind the scenes, responsible for operating and maintaining image processing machines and other inspection equipment with precision and expertise. From calibrating sensors to troubleshooting technical issues, these skilled professionals play a critical role in ensuring the smooth and efficient functioning of inspection systems, thereby safeguarding product integrity and upholding the reputation of pharmaceutical brands. By investing in training and development for inspection technicians, companies can ensure that their inspection processes remain robust, reliable, and responsive to evolving industry trends and technologies.

Conclusion:

In conclusion, image processing machines and machine learning are revolutionizing the landscape of pharmaceutical inspection, empowering manufacturers to achieve unprecedented levels of precision, efficiency, and reliability in quality control. By harnessing the power of these technologies and partnering with visual inspection professionals and inspection technicians, companies can ensure that every product meets the highest standards of safety and efficacy, thereby building trust with consumers and advancing the cause of public health. As the industry continues to evolve, the role of image processing machines and machine learning in pharmaceutical manufacturing will only continue to grow, driving innovation and excellence in quality assurance.