Advanced Vision Inspection Systems for Pharmaceutical Packaging

In the pharmaceutical industry, ensuring the highest standards of quality for packaging components like plastic caps, bottles, and spray pumps is crucial. Our vision inspection systems are designed to meet these stringent requirements by incorporating advanced algorithmic programming and artificial intelligence (AI). These technologies enable high-precision inspection accuracy and significantly reduce error rates, ensuring that every component meets the rigorous quality standards necessary for pharmaceutical applications.

Application of Vision Inspection Systems in Pharmaceutical Packaging

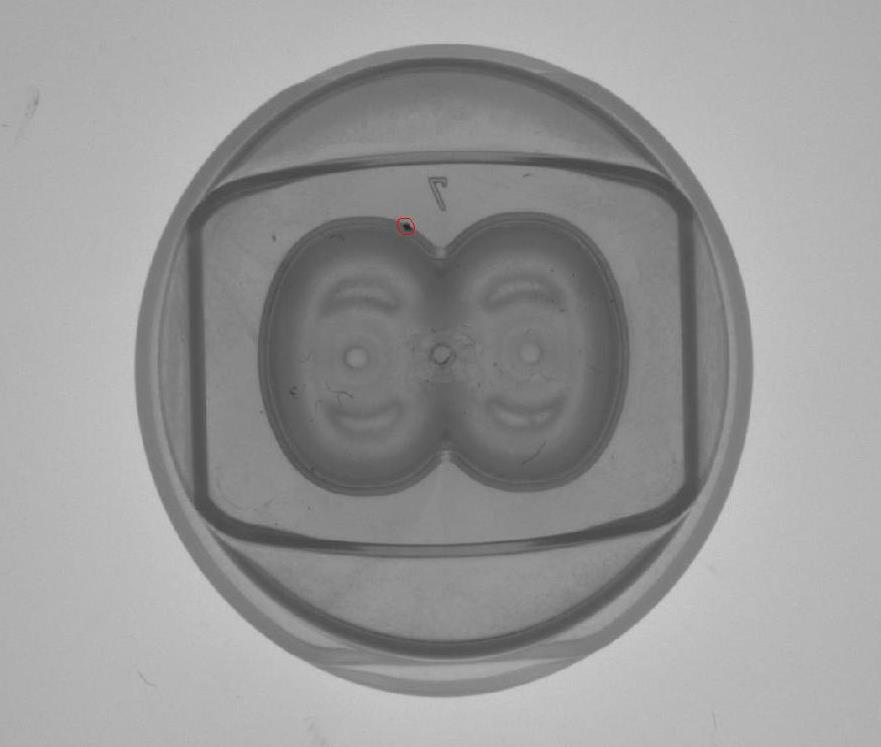

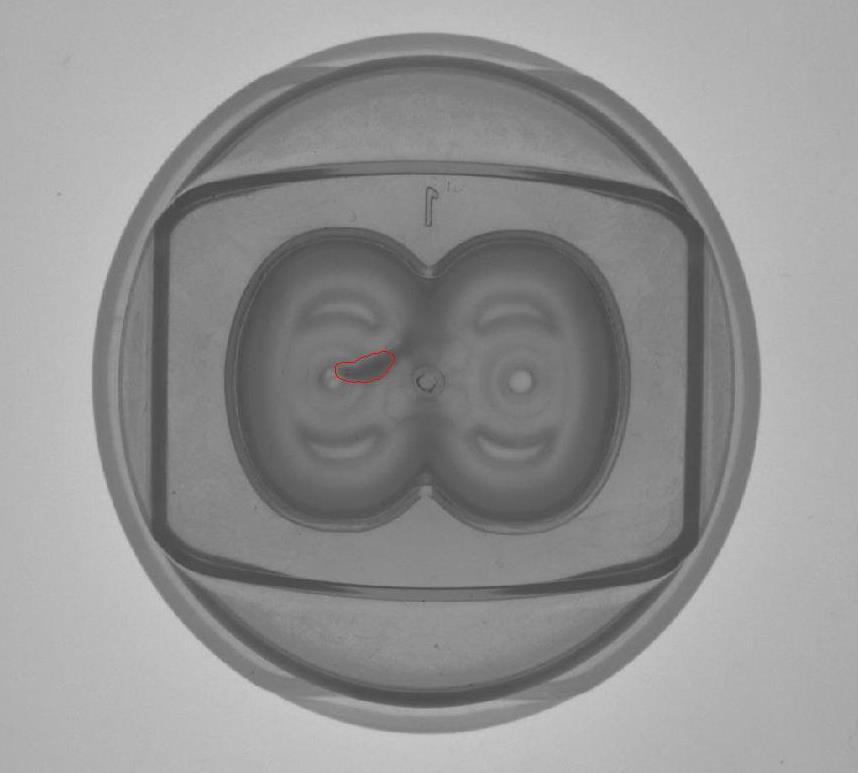

- Plastic Caps

- Thread Accuracy: Ensures that threads are properly formed and consistent, preventing sealing issues and contamination risks.

- Surface Defects: Detects scratches, dents, black spot , damage, foreigner matter and other surface imperfections that could compromise the integrity or functionality of the caps.

- Dimensional Consistency: Measures key dimensions to ensure caps fit securely on bottles, maintaining sterility and product integrity.

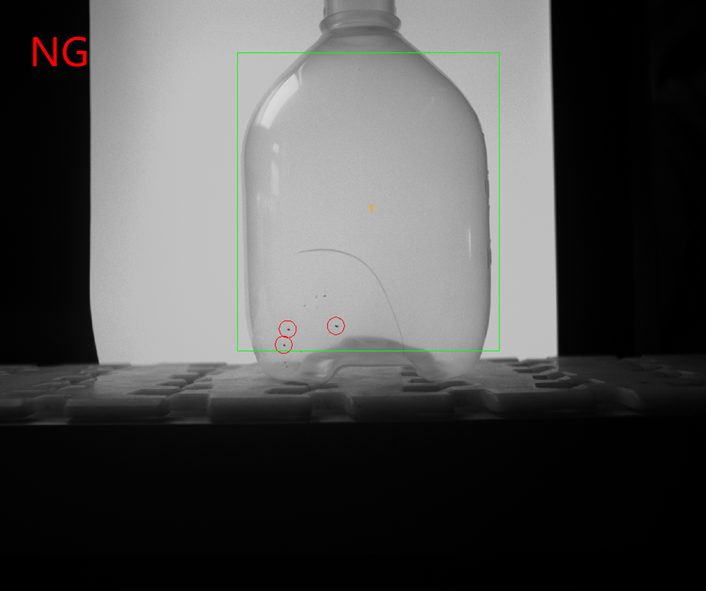

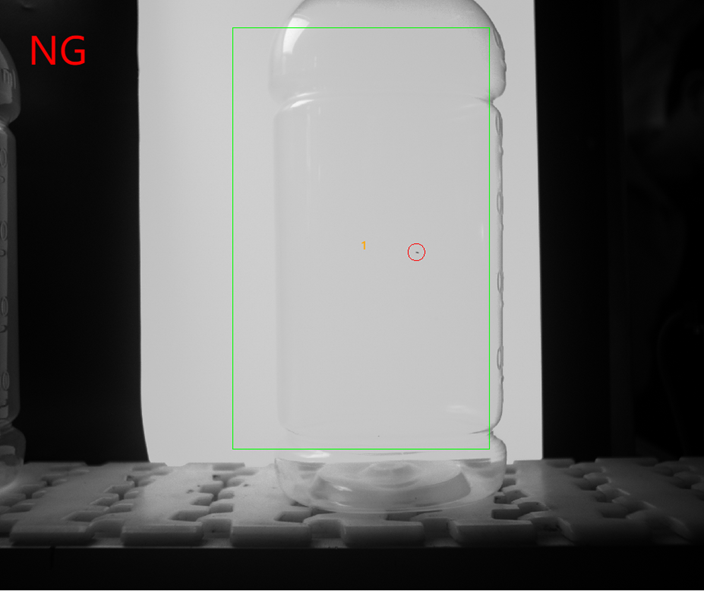

- Bottles

- Shape and Size Verification: Ensures bottles are of the correct shape and size to fit with caps and other packaging components.

- Surface and Internal Defects: Detects cracks, bubbles, foreign matter , black spot or any structural weaknesses that could lead to contamination or leaks.

- Color and Clarity: Verifies that bottles are the correct color and free from discoloration or cloudiness, ensuring clear visibility of the contents.

- Spray Pumps

- Assembly Verification: Checks that all parts of the spray pump are correctly assembled, ensuring proper function and dosage accuracy.

- Nozzle and Spray Pattern Inspection: Ensures that the nozzle is free from blockages and that the spray pattern meets specifications for effective delivery.

- Functional Testing: Simulates the pump action to verify proper functionality and consistent performance.

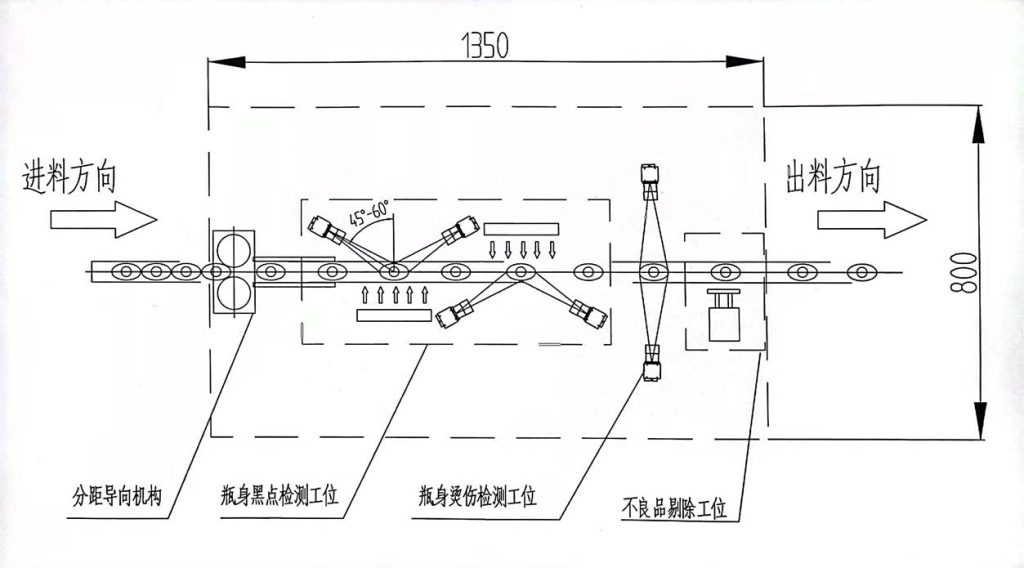

All-round inspection of top, bottom, left and right, and middle surface

Our vision inspection systems leverage the power of AI and sophisticated algorithms to enhance the inspection process. This combination provides several key advantages:

- High Precision Inspection

- AI-Powered Algorithms: Utilizing machine learning algorithms trained on extensive datasets allows our systems to recognize and classify defects with exceptional accuracy. This ensures that even minor defects are detected.

- Adaptive Learning: The system continuously improves its performance by learning from new data and adapting to changes in production environments, such as variations in lighting or component appearance.

- Reduced Error Rates

- Enhanced Defect Detection: AI algorithms distinguish between true defects and acceptable variations, reducing both false positives and false negatives. This leads to more accurate and reliable inspections.

- Consistent Performance: Unlike human inspectors, AI systems provide uniform inspection quality without fatigue, ensuring consistent results across all production runs.

Integration and Adaptability

- Seamless Integration

- Modular Design: Our vision systems are designed to integrate seamlessly with existing production lines, providing flexibility to meet specific inspection needs.

- Real-Time Monitoring: The system offers real-time monitoring and reporting, allowing for immediate corrective actions and minimizing downtime.

- Scalability

- Versatile Application: AI algorithms can be adapted to inspect a wide range of products, from different types of caps and bottles to complex spray pump assemblies.

- Future-Proof Technology: Our systems are built to evolve with advancements in AI and imaging technology, ensuring long-term value and adaptability to new inspection challenges.

According to the color of the product, the characteristics of the defect and the location of the defect, a program can be developed according to the customer’s requirements to achieve the purpose of detection.