Advanced vision inspection machines play a crucial role in ensuring the quality and safety of IV solutions in pharmaceutical manufacturing. These automated inspection systems are designed to detect contaminants and ensure sterile production. By using machine vision technology, these machines can perform high speed inspections with precision, detecting even the smallest visible particles that could compromise the integrity of the drugs.

IV bags, bottles, vials, ampules, and other containers undergo thorough inspection to ensure that they are free of foreign matters , particles and other contaminants. Inspection algorithms, advanced optics, and inspection software work together to provide real time inspection results, meeting strict safety regulations in pharmaceutical packaging.

Machine learning and artificial intelligence are also being increasingly integrated into these advanced inspection systems to improve efficiency and accuracy. With high resolution imaging capabilities, these machines can achieve contamination free production, thereby upholding the quality of IV solutions.

Safety regulations in the pharmaceutical industry necessitate the use of advanced inspection systems to maintain contamination free production. These machines utilize inspection software, machine learning, and artificial intelligence to enhance inspection accuracy and efficiency. By incorporating AI in pharma, industrial automation is revolutionizing the quality control processes in healthcare technology.

Through the use of advanced vision inspection, pharmaceutical companies can improve production line efficiency, reduce the risk of product recalls, and uphold the highest standards of quality in IV solution manufacturing. These systems are pivotal in ensuring that IV solutions meet the stringent quality standards set by regulatory bodies, ultimately safeguarding patient health and well being.

In conclusion, advanced vision inspection is indispensable in the pharmaceutical industry, particularly in IV solution production. By investing in advanced inspection systems, companies can guarantee the safety, integrity, and quality of their products, ultimately contributing to the advancement of healthcare technology.

The Role of Advanced Vision Inspection in Pharmaceutical Manufacturing

Having advanced vision inspection systems in pharmaceutical manufacturing plays a crucial role in ensuring the quality and safety of IV solutions. These machines utilize cutting edge machine vision technology to automate inspection processes, leading to more efficient and accurate quality control. By detecting contaminants such as glass particles in IV bags, bottles, vials, and ampules, these systems help maintain sterile production environments and uphold stringent safety regulations.

The high speed inspection capabilities of advanced vision inspection machines enable real time detection of particles that could compromise drug integrity. By employing advanced optics and inspection software, these systems can identify and address any issues on the production line swiftly, improving overall efficiency in pharmaceutical packaging. Machine learning and AI in pharma are also being integrated into these systems to enhance their inspection algorithms and ensure contamination free production.

With high resolution imaging and advanced inspection systems, pharmaceutical manufacturers can rest assured that their IV solutions meet the highest quality standards. These technologies not only enhance production line efficiency but also contribute to the advancement of healthcare technology. By investing in advanced vision inspection for IV solution quality, pharmaceutical companies can guarantee the safety and effectiveness of their products for patients worldwide.

Quality Control and Automated Inspection: Ensuring Contamination Free Production in IV Solutions

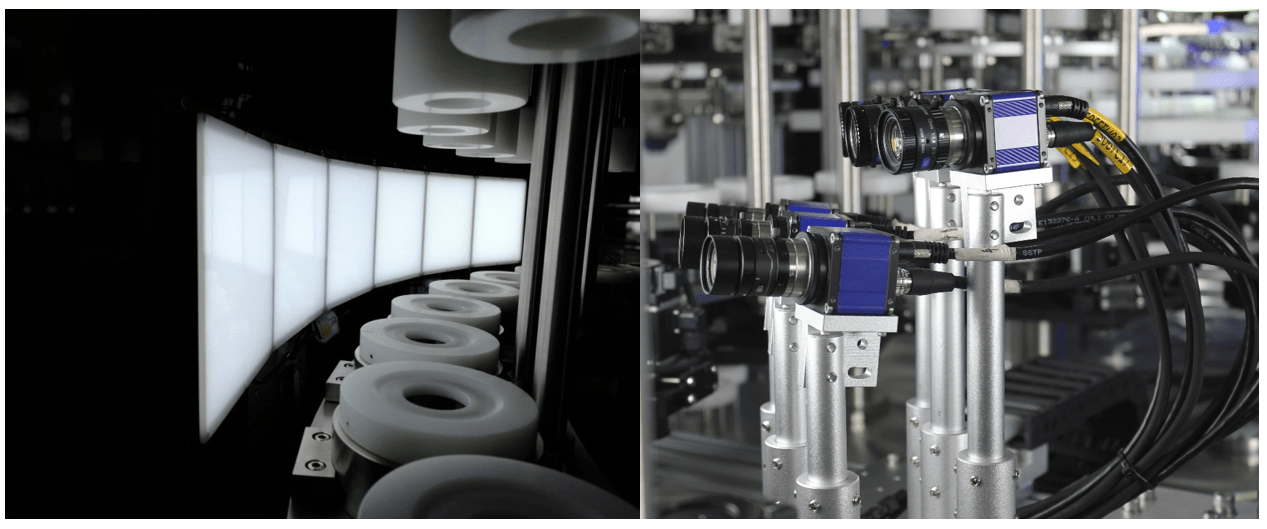

Quality control and automated inspection are vital components in ensuring contamination free production in IV solutions. Advanced vision inspection machines play a crucial role in the pharmaceutical manufacturing process by providing high speed inspection and contamination detection capabilities using machine vision technology. These machines are equipped with advanced optics and high resolution imaging sensors to detect particles and ensure drug integrity during production.

Automated inspection systems use inspection algorithms, real time monitoring, and inspection software to analyze IV bags, bottles, vials, ampules, and glass particles for any contaminants. By employing machine learning and artificial intelligence in pharmaceutical packaging, these systems adhere to safety regulations and enhance production line efficiency in healthcare technology.

The integration of AI in pharma has revolutionized the way IV solutions are inspected, ensuring sterile production and maintaining quality standards. Through the use of advanced inspection systems, pharmaceutical companies can guarantee contamination free production and uphold the integrity of their products. By leveraging machine vision technology and automated inspection processes, the pharmaceutical industry continues to advance in ensuring the highest quality IV solutions for patients worldwide.

By implementing these cutting edge technologies, companies can stay ahead of the curve in pharmaceutical manufacturing, providing safe and effective IV solutions to healthcare providers and patients. With the continuous evolution of industrial automation and inspection technology, the future of IV solution quality looks brighter than ever.

For more information on quality control and automated inspection in pharmaceutical manufacturing, visit the wikipedia page on quality control.

The Core Functions of Advanced Vision Inspection Machines:

- Label Inspection: The accuracy and legibility of labels on IV solution containers are crucial for proper identification and usage. Advanced vision inspection machines meticulously scan labels, ensuring compliance with regulatory requirements and minimizing the risk of errors.

- Fill Level Inspection: Precise fill levels are essential to guarantee the correct dosage of medication for patients. Vision systems meticulously measure and verify the volume of liquid in each IV solution container, mitigating the risk of under-dosing or over-dosing.

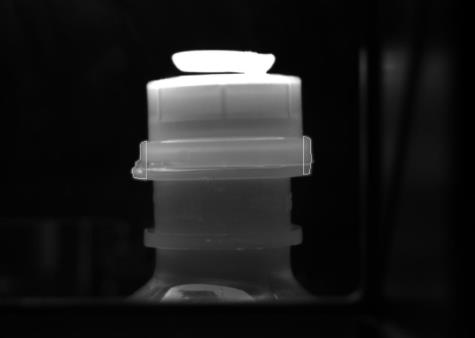

- Cap and Seal Integrity: Any compromise in the integrity of caps and seals can lead to contamination or leakage, posing a significant threat to patient safety. Advanced vision inspection machines meticulously examine caps and seals, ensuring they are securely in place and free from defects.

- Particle Detection: Even the tiniest particles in IV solutions can pose serious health risks to patients. Vision inspection systems employ advanced algorithms to detect and reject solutions containing visible particles, safeguarding patient well-being.

- Color and Clarity Verification: IV solutions must maintain their intended color and clarity to ensure quality and efficacy. Vision inspection machines meticulously analyze the color and clarity of solutions, flagging any deviations that may indicate impurities or degradation.

- Barcode Validation: Accurate barcode information is essential for proper identification and tracking of IV solution containers throughout the supply chain. Advanced vision inspection machines verify barcode accuracy, minimizing the risk of errors in inventory management and distribution.

- Print Quality Assurance: Vital information such as batch numbers and expiration dates must be clearly printed on IV solution containers. Vision inspection systems scrutinize print quality, ensuring legibility and compliance with regulatory standards.

- Container Integrity Examination: Any defects in the containers themselves can compromise the safety and efficacy of IV solutions. Advanced vision inspection machines meticulously inspect containers for cracks, chips, or other structural defects, ensuring only pristine containers make it to the market.

The Power of Machine Learning and AI in Pharma: From IV Bag Inspection to Real Time Analysis

Machine learning and AI have revolutionized the pharmaceutical industry, particularly in the realm of IV solution production. Advanced vision inspection machines equipped with machine learning algorithms and AI technology are now utilized for automated inspection of IV bags, bottles, vials, ampules. These high speed inspection systems play a crucial role in ensuring quality control, detecting contamination, and maintaining sterile production environments.

Machine vision technology, powered by AI, enables real time inspection of pharmaceutical packaging to guarantee drug integrity and compliance with safety regulations. By utilizing advanced optics and high resolution imaging, these systems can detect particles as small as a few microns, ensuring contamination free production. Moreover, the integration of inspection software enhances the efficiency of production lines, reducing the risk of errors and enhancing overall productivity.

The incorporation of machine learning and AI in pharmaceutical manufacturing not only improves IV solution quality but also enhances healthcare technology as a whole. By utilizing AI driven inspection algorithms, companies can streamline their production processes, minimize the risk of defects, and adhere to stringent regulatory standards. As the industry continues to embrace industrial automation, the role of machine learning and AI in ensuring safe and reliable pharmaceutical products becomes increasingly vital.

Looking to the Future: The Impact of Advanced Inspection Systems on Industrial Automation and Healthcare Technology.

The impact of advanced inspection systems on industrial automation and healthcare technology is undeniable. These cutting edge technologies, such as advanced vision inspection machines, have revolutionized the way pharmaceutical manufacturing and quality control are carried out. With automated inspection processes, contamination detection, and sterile production becoming more efficient and accurate, the future of the industry looks promising.

High speed inspection capabilities provided by machine vision technology have allowed for precise particle detection, ensuring drug integrity and compliance with safety regulations. The production line efficiency has significantly improved, thanks to real time inspection and advanced inspection algorithms.

In healthcare technology, the inspection of IV solutions, including IV bags, bottles, vials, ampules, and the detection of glass particles, has become more advanced and reliable. With the use of advanced optics, inspection software, and machine learning algorithms, the quality of pharmaceutical packaging has never been better.

The integration of AI in pharma has further enhanced industrial automation processes, making IV solution quality inspections more accurate and contamination free. The use of high resolution imaging technology has enabled the detection of even the smallest particles, ensuring the production of safe and high quality medical products.

Visual Inspection Machine For IV PP bottle