The global hemodialysis market is witnessing significant growth driven by the rising prevalence of chronic kidney disease (CKD) and end-stage renal disease (ESRD). As the demand for dialysis treatments escalates, so does the need for innovative solutions that enhance production efficiency, ensure patient safety, and improve treatment outcomes. Hemodialysis tube sets, a critical component of the dialysis process, are at the forefront of these innovations, playing a crucial role in the overall effectiveness and safety of dialysis therapy.

The Hemodialysis Market: An Overview

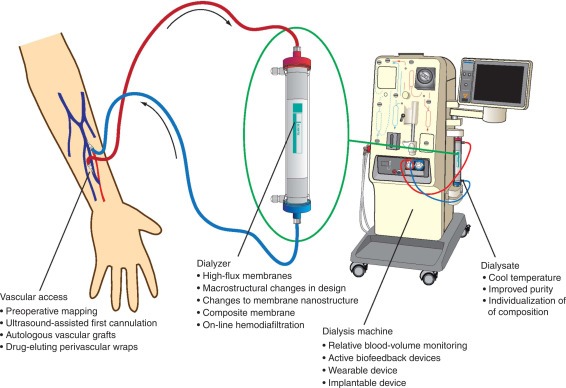

Hemodialysis is a medical procedure that filters waste products and excess fluids from the blood when the kidneys can no longer perform this function. This treatment is essential for patients with severe CKD or ESRD, providing a lifeline to maintain their health and quality of life. The hemodialysis market encompasses a wide range of products, including dialysis machines, dialyzers, tubing systems, and various accessories.

Market Growth Drivers

Several factors are driving the growth of the hemodialysis market:

- Increasing Prevalence of Kidney Diseases: The incidence of CKD and ESRD is rising globally due to factors such as diabetes, hypertension, and an aging population. This increase in kidney diseases directly correlates with a higher demand for dialysis treatments.

- Technological Advancements: Innovations in dialysis technology, including more efficient machines and safer, more effective tubing systems, are enhancing the overall treatment experience for patients and providers.

- Government and Healthcare Initiatives: Governments and healthcare organizations are investing in dialysis infrastructure and subsidizing treatment costs, particularly in developing regions, to improve access to essential dialysis services.

- Rising Awareness and Diagnosis: Improved awareness and diagnostic capabilities are leading to earlier detection of kidney diseases, resulting in more patients requiring dialysis treatment.

Hemodialysis Tube Set Production: Precision and Innovation

Hemodialysis tube sets are a vital component of the dialysis process, ensuring the safe and efficient transfer of blood between the patient and the dialysis machine. The production of these tube sets involves several critical steps and requires meticulous attention to detail to maintain high standards of quality and safety.

Production Process

The production of hemodialysis tube sets involves several stages:

- Material Selection: The tubing is typically made from medical-grade materials such as polyvinyl chloride (PVC) or silicone, which must be biocompatible and durable to withstand repeated use.

- Extrusion and Molding: The selected materials are extruded into tubes of precise dimensions. Molding processes are then used to create connectors and other components that are integral to the tubing system.

- Assembly: The various components are assembled into a complete tube set. This stage requires precise alignment and connection of parts to ensure a secure and leak-proof system.

- Sterilization: The assembled tube sets undergo sterilization processes, such as gamma irradiation or ethylene oxide treatment, to eliminate any potential contaminants and ensure they are safe for medical use.

- Quality Control: Rigorous quality control measures are implemented throughout the production process. This includes visual inspections, pressure testing, and functional checks to ensure each tube set meets stringent standards.

Innovations in Production

Innovations in the production of hemodialysis tube sets are focused on enhancing efficiency, precision, and safety:

- Automation: Automated assembly machines, equipped with advanced robotics and sensors, are revolutionizing the production process. These machines can assemble tube sets with exceptional precision, significantly reducing the risk of human error and contamination.

- Advanced Materials: Research and development in material science are leading to the creation of new biocompatible materials that offer improved durability and performance. These materials can reduce the risk of allergic reactions and other complications.

- Smart Technologies: Integration of smart technologies, such as embedded sensors and data tracking systems, allows for real-time monitoring of the tube sets during use. This can help detect potential issues early and improve overall treatment safety.

Patient Safety: A Paramount Concern

Ensuring patient safety is the foremost priority in the production and use of hemodialysis tube sets. Any compromise in the quality or integrity of these components can have serious repercussions for patient health. Here are some key considerations for patient safety in the context of hemodialysis tube sets:

Sterilization and Contamination Control

Sterilization is critical to prevent infections and other complications. Advanced sterilization techniques, combined with stringent contamination control measures, ensure that tube sets are free from harmful microorganisms and contaminants. Automated assembly further minimizes human contact, reducing the risk of contamination during production.

Biocompatibility

The materials used in hemodialysis tube sets must be biocompatible to prevent adverse reactions when in contact with blood and tissues. Ongoing research into new materials aims to enhance biocompatibility, reducing the likelihood of allergic reactions and other complications.

Leak Prevention and Integrity

The integrity of the tube sets is vital to ensure safe and effective dialysis treatment. Any leaks or disconnections can lead to serious health risks. Quality control measures, including pressure testing and functional checks, help ensure that each tube set is secure and reliable.

Traceability and Monitoring

Advanced data integration and traceability systems allow for comprehensive monitoring of the production process and the usage of tube sets. This data is invaluable for quality assurance and regulatory compliance, ensuring that any issues can be quickly identified and addressed.

Conclusion

Automated hemodialysis tube assembly machines represent a significant advancement in the field of medical device manufacturing. By automating the complex and delicate process of assembling hemodialysis tubes, these machines ensure higher precision, efficiency, and safety, ultimately improving the quality of care for patients undergoing dialysis treatment. As technology continues to evolve, the capabilities of automated assembly machines will expand, driving further innovations in the healthcare industry and setting new standards for medical device production. The transition to automation not only addresses current challenges but also paves the way for a future where high-quality, reliable medical devices are more accessible to those in need.

Dialysis Blood Tube Assembly Line