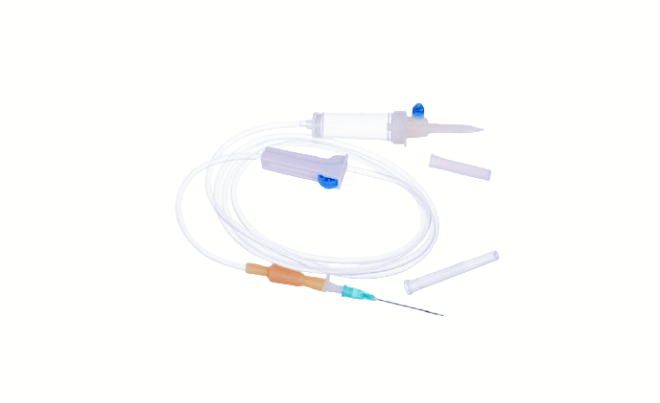

In medical consumables manufacturing, assembling Intravenous (IV) sets is a pivotal process. These sets are lifelines in healthcare, delivering fluids and medications directly into patients’ veins. Crafting them demands precision and adherence to meticulous protocols. In this exhaustive factory guide, we’ll navigate through the step-by-step process of IV set assembly.

Understanding the Machinery and Components

Before delving into the assembly process, it’s crucial to comprehend both the machinery involved and the components of an IV set:

1. Automated Assembly Machines: These specialised machines streamline production, ensuring efficiency and consistency.

2. Tubing: Flexible, medical-grade tubing carries fluids from the IV bag to the patient.

3. Needle or Catheter: The entry point into the patient’s vein, facilitating the delivery of fluids and medications.

4. Drip Chamber: This component regulates fluid flow and provides a visual indicator for monitoring.

5. Regulator/Clam*: Adjusts the flow rate of the IV set, crucial for precise administration of fluids.

6. Injection Port: Facilitates the administration of additional medications without disrupting the central IV line.

7. Filter: Ensures the removal of particulate matter or air bubbles from the fluid, enhancing patient safety.

8. Adapter/Spike: Connects the IV set securely to the fluid container, maintaining a sealed system.

Step-by-Step Assembly Process in the Factory Setting

Now, let’s navigate through the intricate process of IV set assembly within a factory environment:

Step 1: Machine Setup and Calibration

Begin by configuring the automated assembly machine according to the specifications of the produced IV set. Calibrate the machine to ensure optimal performance and accuracy throughout the assembly process.

Step 2: Component Preparation

Prepare all components required for IV set assembly, ensuring they meet quality standards and regulatory requirements. Before proceeding, components should be meticulously inspected for defects or irregularities.

Step 3: Tubing Attachment

Attach the tubing to the appropriate connectors using the automated assembly machine as per the predetermined design. Ensure proper alignment and secure fixation to prevent leaks or disconnections during use.

Step 4: Integration of Additional Components

Incorporate additional components such as the drip chamber, regulator/clamp, injection port, filter, and adapter/spike into the assembly process. Each component must be seamlessly integrated into the IV set precisely and accurately.

Step 5: Quality Control Measures

Implement rigorous quality control measures at each stage of the assembly process. Use automated inspection systems and manual checks to detect deviations from the desired standards. Reject any units that fail to meet quality criteria to uphold product integrity.

Step 6: Final Testing and Packaging

Conduct comprehensive testing on assembled IV sets to verify functionality, fluid flow rate accuracy, and structural integrity. Once validated, package the IV sets securely, ensuring they are labelled accurately with essential information such as batch numbers, expiration dates, and manufacturing details.

Enhancing Efficiency and Safety in IV Set Assembly

Efficiency and safety are paramount in IV set assembly within a factory setting. Here are some key strategies to optimise these aspects:

– **Employee Training**: Provide comprehensive training programs to equip workers with the necessary skills and knowledge for IV set assembly.

– **Continuous Improvement**: Foster a culture of continuous improvement, encouraging feedback and implementing innovative solutions to enhance efficiency and quality.

– **Adherence to Regulatory Standards**: Maintain strict compliance with regulatory standards and guidelines governing medical device manufacturing to ensure product safety and legality.

Conclusion

Mastering the assembly of IV sets within a factory environment demands meticulous attention to detail, precision, and adherence to stringent quality standards. By following this step-by-step guide and leveraging advanced technologies such as automated assembly machines, manufacturers can streamline the production process while upholding the highest quality and safety standards.

IV set assembly line