Introduction:

In the realm of pharmaceutical manufacturing, maintaining product integrity is paramount. A crucial component in achieving this goal is the seal liner for bottles. These dynamic seals play a pivotal role in preserving the quality and safety of pharmaceutical products. In this article, we delve into the significance of seal liners for bottles and how they actively contribute to enhancing packaging integrity.

The Significance of Seal Liners for Bottles:

Seal liners for bottles serve as a robust barrier, actively shielding pharmaceutical products from external contaminants such as moisture, oxygen, and impurities. By forming a secure seal, they prevent leakage and tampering, ensuring the potency and efficacy of medications remain intact.

Seal liners for bottles actively protect pharmaceutical products by creating a secure barrier against external contaminants.

Types of Seal Liners for Bottles:

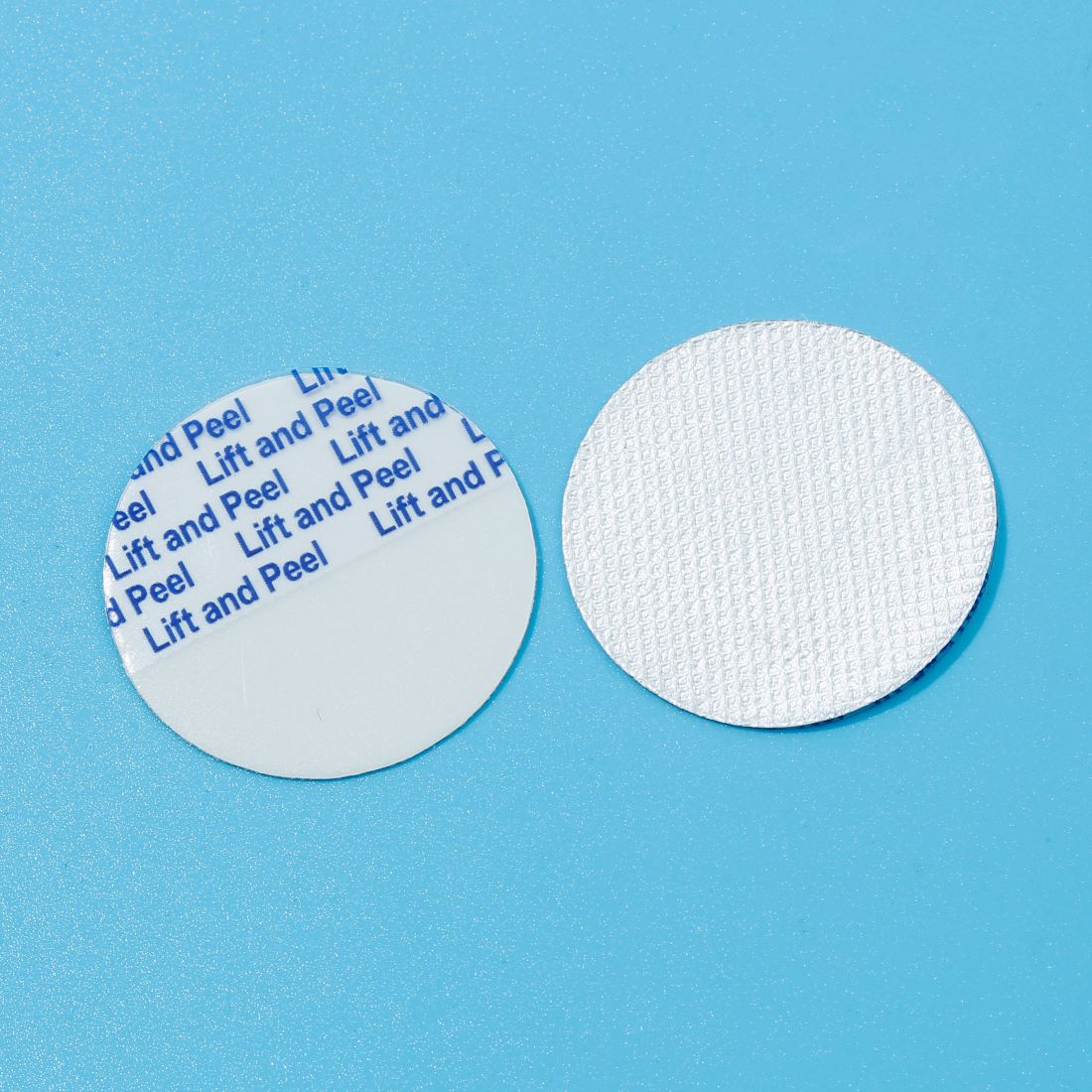

A diverse range of seal liners is available, each tailored to meet specific packaging requirements and product protection needs. These include induction seal liners, pressure-sensitive liners, foam liners, and pulp/poly liners. Each type offers unique features and benefits, ensuring compatibility with various bottle materials and contents.

Active Voice Example: Induction seal liners actively form a hermetic seal upon application to bottles, preventing oxygen ingress and maintaining product freshness.

Benefits of Seal Liners for Bottles:

1. Preservation of Product Integrity: Seal liners for bottles actively maintain the integrity of pharmaceutical products, safeguarding them from contamination and preserving their potency.

2. Tamper-Evidence: These seal liners provide clear evidence of tampering, instilling confidence in consumers regarding the safety and authenticity of the products.

3. Extension of Shelf Life: By minimizing exposure to external elements, seal liners for bottles actively extend the shelf life of pharmaceutical products, reducing waste and maximizing profitability.

Seal liners for bottles actively extend the shelf life of pharmaceutical products by minimizing exposure to external elements.

Selecting the Right Seal Liner for Bottles:

Choosing the appropriate seal liner for bottles is crucial to ensure compatibility with the packaging material, product formulation, and intended use. Factors to consider include bottle type, closure mechanism, product sensitivity to moisture and oxygen, and adherence to regulatory standards.

When selecting a seal liner for bottles, consider factors such as bottle type, product sensitivity, and regulatory compliance.

Conclusion:

Seal liners for bottles play a vital role in enhancing pharmaceutical packaging integrity, ensuring product safety and regulatory compliance. By embracing these active seals and selecting the right ones for their packaging needs, pharmaceutical manufacturers can uphold their commitment to quality and excellence.

Aluminum foil