Introduction: In the intricate world of medical disposable manufacturing and pharmaceutical production, ensuring the highest standards of quality is paramount. Among the key processes that uphold this standard is quality control. In this article, we delve into the nuances of quality control, its importance, and its distinction from quality assurance.

What is Quality Control?

Quality control (QC) encompasses the measures and procedures employed to monitor and regulate the quality of products throughout the manufacturing process. It involves systematic inspection, testing, and analysis to identify deviations from predefined standards. In the context of medical disposable manufacturing and pharmaceuticals, QC ensures that every product meets stringent regulatory requirements and adheres to industry standards.

Quality Assurance vs. Quality Control: Understanding the Difference

While quality control and quality assurance (QA) are often used interchangeably, they represent distinct facets of the manufacturing process. Quality assurance focuses on the implementation of systems and processes to prevent defects from occurring in the first place. On the other hand, quality control is concerned with detecting and rectifying deviations that may arise during production. In essence, QA is proactive, while QC is reactive.

The Role of a Quality Control Inspector

A quality control inspector plays a pivotal role in upholding quality standards within a manufacturing facility. Their responsibilities include conducting inspections at various stages of production, performing tests to assess product quality, and documenting findings. These inspectors possess a keen eye for detail and a thorough understanding of regulatory requirements, ensuring that only products meeting specifications are released to the market.

Importance of Quality Control in Medical Disposable Manufacturing

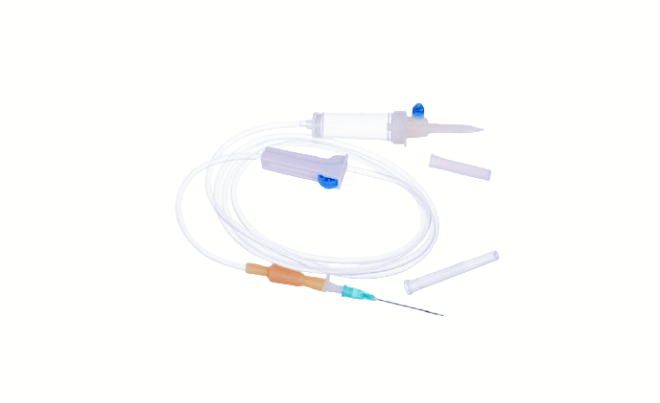

In the healthcare industry, the ramifications of substandard products can be dire. Quality control serves as a safeguard against potential risks to patient safety and ensures the efficacy and reliability of medical disposables. By implementing robust QC measures, manufacturers mitigate the likelihood of defects, contamination, and non-compliance with regulatory standards, thereby safeguarding both patients and their reputation.

Quality Control vs. Quality Assurance: A Collaborative Approach

While QC and QA operate distinctively, they are interdependent components of a comprehensive quality management system. By integrating both approaches, manufacturers can achieve synergy in their efforts to deliver superior products. QA sets the foundation for quality by establishing processes and standards, while QC validates adherence to these standards through meticulous testing and inspection.

Conclusion: In the dynamic landscape of medical disposable manufacturing and pharmaceutical production, quality control stands as a linchpin in ensuring product integrity and patient safety. By embracing a proactive approach to QC and fostering collaboration between quality control and quality assurance functions, manufacturers can uphold the highest standards of quality and compliance.