Introduction:

In the intricate landscape of pharmaceutical manufacturing, ensuring the safety and integrity of medications is paramount. Every component of the packaging plays a crucial role, and one such component that often goes unnoticed is the bottle cap seal liner. These small but vital elements serve as the first line of defense, protecting pharmaceutical products from contamination, tampering, and environmental factors. This comprehensive guide delves into custom bottle cap seal liners, exploring their significance in pharmaceutical packaging and how they contribute to product quality and safety.

Understanding Custom Bottle Cap Seal Liners:

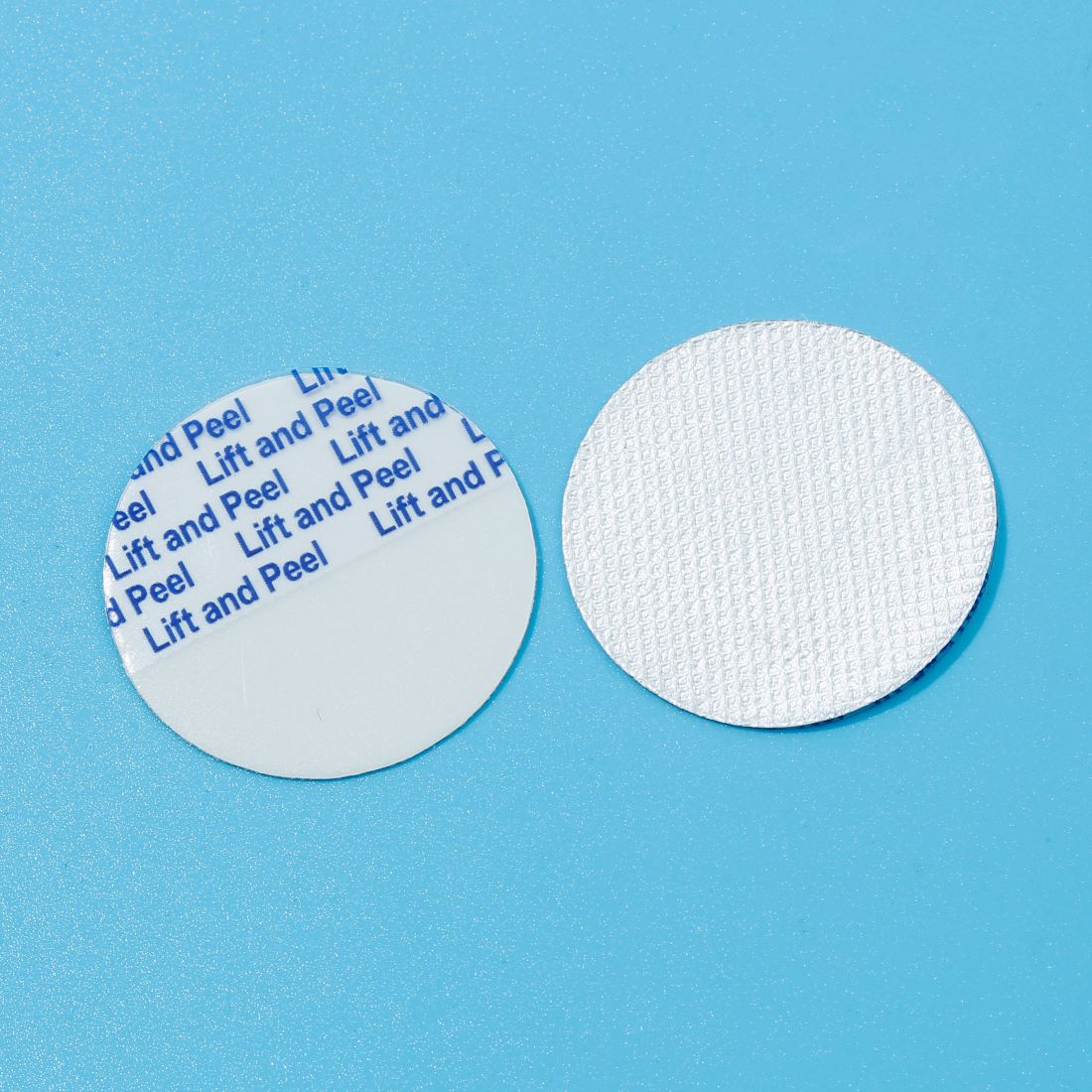

Custom bottle cap seal liners represent a tailored solution to the specific needs of pharmaceutical packaging. Unlike standard liners, which offer generic protection, custom liners are designed to fit individual bottles and formulations’ unique dimensions and requirements. This customization ensures a precise seal that enhances product security and maintains the medication’s integrity throughout its shelf life.

Types of Custom Bottle Cap Seal Liners:

1. Material Customization:

– Custom bottle cap seal liners allow for the selection of materials tailored to the specific properties of the pharmaceutical product.

– Options may include polyethylene (PE) foam for its chemical resistance, polypropylene (PP) foam for its durability, or induction seal liners for superior barrier properties.

– Material customization ensures optimal compatibility and protection against moisture, gases, and other contaminants.

2. Thickness Variations:

– Custom liners offer flexibility in thickness, allowing manufacturers to choose the ideal level of protection for their products.

– Thicker liners provide enhanced sealing and tamper-evident features crucial for high-value or sensitive pharmaceuticals.

Thinner liners may be preferred for cost-effective packaging solutions without compromising safety or efficacy.

3. Adhesive Properties:

– Custom bottle cap seal liners can be customized with specific adhesive properties to suit different bottle materials and closure systems.

– Pressure-sensitive liners, for instance, offer easy application and tamper evidence while providing a secure seal against leaks and contamination.

– Adhesive customization ensures compatibility with various packaging configurations, including glass and plastic bottles.

4. Tamper-Evident Features:

– Custom liners can incorporate specialized tamper-evident features to enhance product security and consumer confidence.

– Induction seal liners, with their airtight seal and puncture resistance, offer robust tamper evidence, ensuring product integrity from production to consumption.

– Tamper-evident customization deters tampering attempts and provides visible indicators of product safety and authenticity.

Benefits of Customization:

The customization of bottle cap seal liners in pharmaceutical packaging offers several tangible benefits for manufacturers and consumers alike:

– Enhanced Product Protection: Custom liners provide tailored protection against external contaminants, moisture, and tampering, safeguarding the efficacy and safety of pharmaceutical products.

– Improved Brand Integrity: Customized packaging solutions reinforce brand identity and trust, signaling a commitment to quality and excellence in pharmaceutical manufacturing.

– Regulatory Compliance: Custom liners can be designed to meet specific regulatory requirements and industry standards, ensuring compliance with pharmaceutical packaging guidelines and regulations.

Future Trends and Innovations:

As the pharmaceutical industry continues to evolve, custom bottle cap seal liners are expected to witness advancements and innovations to meet the changing needs of manufacturers and consumers. Emerging trends may include:

– Sustainability: Developing eco-friendly materials and recyclable liners to address environmental concerns and promote sustainability in pharmaceutical packaging.

– Smart Packaging: Integrating intelligent technologies, such as RFID tags and NFC chips, into custom liners for real-time tracking, authentication, and product information retrieval.

Conclusion:

Custom bottle cap seal liners represent a tailored solution to the diverse needs of pharmaceutical packaging, offering enhanced protection, brand integrity, and regulatory compliance. Manufacturers can optimize product safety and consumer trust by leveraging customization options in materials, thickness, adhesive properties, and tamper-evident features. As the industry embraces innovation and sustainability, custom liners are poised to play a pivotal role in shaping the future of pharmaceutical packaging, ensuring the continued safety and efficacy of medications worldwide.

Aluminum foil

Deutsch

Deutsch हिन्दी

हिन्दी 日本語

日本語 한국어

한국어 Монгол

Монгол Português

Português Русский

Русский Español

Español தமிழ்

தமிழ் Türkçe

Türkçe Українська

Українська Tiếng Việt

Tiếng Việt