In the fast-paced world of pharmaceutical manufacturing, having the right equipment can make all the difference between success and stagnation. From production to packaging, every step requires precision and reliability. In this article, we delve into the key equipment that pharmaceutical manufacturers rely on to streamline their operations and maintain the highest standards of quality.

Mixing and Blending Equipment

Mixing and blending are fundamental processes in pharmaceutical manufacturing, ensuring uniformity and consistency in the final product. High-shear mixers, granulators, and blenders are essential for homogenizing ingredients and creating the desired formulations.

Tablet Presses and Capsule Fillers

Tablets and capsules are the most common forms of pharmaceutical dosage, making tablet presses and capsule fillers indispensable equipment in any manufacturing facility. These machines accurately dose and compress powdered ingredients into solid forms, ready for packaging.

Sterilization Equipment

Maintaining sterility throughout the manufacturing process is crucial to prevent contamination and ensure product safety. Autoclaves, sterilizers, and depyrogenation ovens are used to sterilize equipment, containers, and packaging materials to meet stringent regulatory standards.

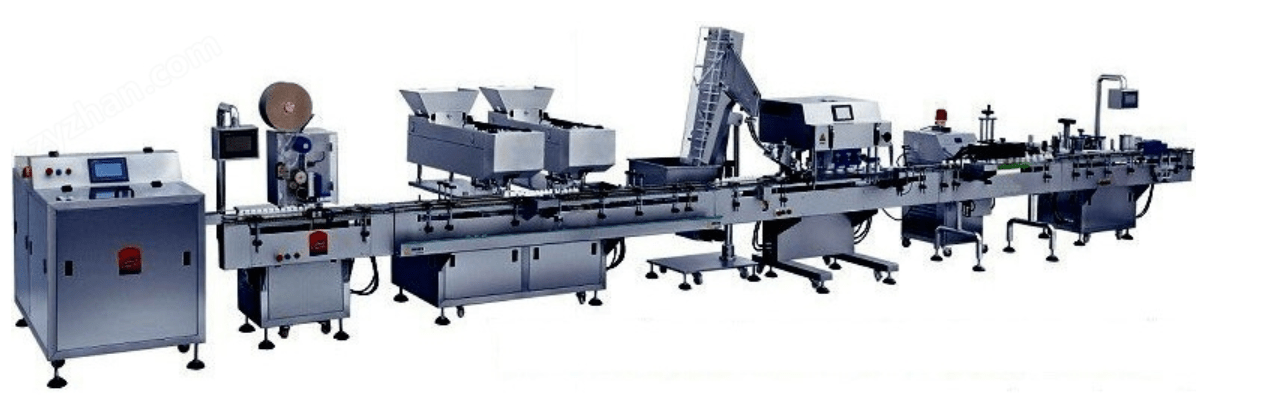

Packaging Machinery

Packaging plays a critical role in protecting pharmaceutical products and maintaining their integrity until they reach the end-user. Automatic filling machines, capping machines, labeling equipment, and blister packaging machines are just a few examples of the advanced machinery used in pharmaceutical packaging.

Analytical Instruments:

Quality control is paramount in pharmaceutical manufacturing, and analytical instruments play a vital role in ensuring the purity, potency, and stability of products. Technologies such as HPLC (High-Performance Liquid Chromatography), spectroscopy, and mass spectrometry enable manufacturers to perform rigorous testing and analysis.

Cleaning and Sanitization Systems

Cleaning equipment and systems are essential for maintaining a hygienic manufacturing environment and preventing cross-contamination. Automated clean-in-place (CIP) systems and washers sanitize equipment and facilities efficiently, minimizing downtime and reducing the risk of product contamination.

Material Handling Equipment

Efficient material handling is essential for optimizing workflow and minimizing manual labor. Conveyors, lifts, and robotic systems streamline the movement of raw materials, intermediates, and finished products, enhancing productivity and reducing the risk of errors.

Environmental Control Systems

Temperature, humidity, and air quality control are critical factors in pharmaceutical manufacturing, especially for processes such as granulation, drying, and coating. HVAC systems, cleanrooms, and environmental monitoring equipment help maintain optimal conditions to ensure product quality and compliance with regulatory standards.

In conclusion, the pharmaceutical industry relies on a diverse range of equipment to meet the demands of modern healthcare and regulatory requirements. Investing in high-quality equipment and adopting innovative technologies can help manufacturers enhance efficiency, maintain product quality, and stay competitive in a rapidly evolving market.

For pharmaceutical companies seeking to enhance their manufacturing capabilities, partnering with reputable equipment manufacturers and suppliers is essential. By leveraging the latest advancements in technology and adhering to best practices, manufacturers can optimize their processes and deliver safe, effective pharmaceutical products to patients worldwide.