Metered Dose Valve Assembly Machines are crucial components in the production of metered dose inhalers used in pharmaceutical manufacturing for inhalation therapy. These machines play a vital role in ensuring the quality control, production efficiency, and dosage accuracy of drug delivery devices. By utilizing precision engineering, automated assembly processes, and process optimization, these machines are able to streamline the assembly line for high speed production of inhaler components.

The assembly equipment used in these machines adheres to strict production standards set for pharmaceutical equipment, ensuring the aerosol valves are assembled with precision and accuracy. Industrial automation is a key feature of these machines, allowing for consistent production quality and reducing the margin of error in assembly. Machine maintenance is also crucial to ensure production capacity is maintained, and quality assurance is upheld throughout the manufacturing process.

In conclusion, understanding the intricacies of metered dose valve assembly machines is essential in the pharmaceutical industry to ensure the production of high quality inhalers for effective patient treatment.

The Importance of Metered Dose in Pharmaceutical Manufacturing

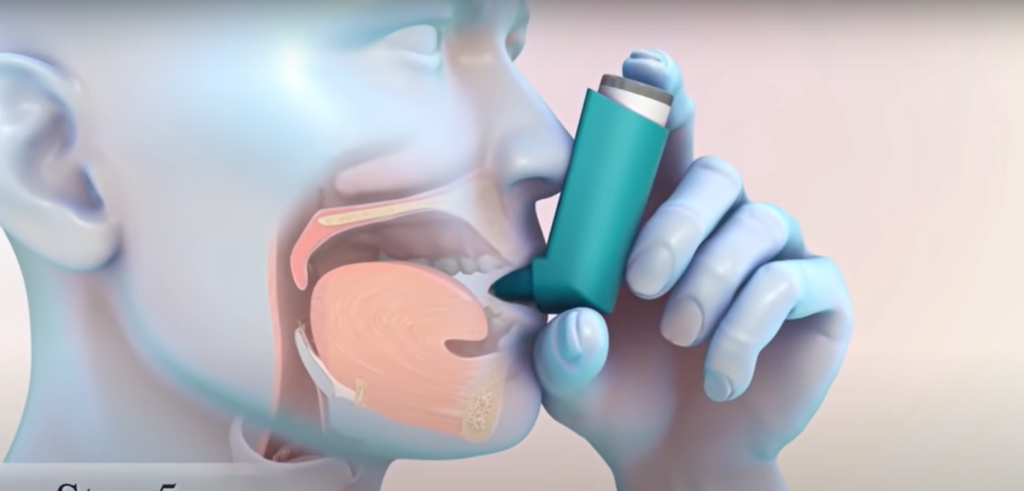

Metered dose is a critical component in pharmaceutical manufacturing. It ensures accurate dosage delivery in drug delivery devices such as inhalers. The valve assembly machine plays a crucial role in the production of metered dose inhalers, contributing to the quality control and production efficiency of aerosol packaging. Precision engineering is key in the assembly line of industrial machinery for drug delivery devices, optimizing the process and meeting production standards. Automated assembly equipment for inhaler components enhances pharmaceutical equipment and industrial automation, maintaining high speed production and quality assurance. Proper machine maintenance is essential to maximize production capacity and ensure dosage accuracy in pharmaceutical manufacturing.

Exploring the Role of Valve Assembly in Inhaler Production

The valve assembly plays a crucial role in inhaler production, ensuring the proper functioning of metered dose inhalers. This automated process involves precision engineering to assemble components such as aerosol valves for drug delivery devices. Quality control measures are implemented to maintain dosage accuracy and production standards. By optimizing the assembly line with industrial machinery, high speed production and quality assurance are achieved. Inhaler technology relies on efficient machine maintenance to sustain production capacity and meet pharmaceutical manufacturing demands.

Machine Maintenance and Quality Control in Pharmaceutical Equipment

Regular machine maintenance and quality control are essential in pharmaceutical equipment to ensure the production of high quality metered dose valve assembly machines for inhaler production. By implementing stringent quality assurance measures and precision engineering techniques, pharmaceutical manufacturing facilities can optimize production efficiency and uphold production standards. Automated assembly processes enhance dosage accuracy and component assembly, leading to the creation of reliable drug delivery devices. Proper machine maintenance and adherence to production standards also contribute to the efficient assembly of inhaler components and aerosol valves in industrial machinery. This commitment to quality control and process optimization is crucial in meeting the demands of high speed production in pharmaceutical equipment for aerosol packaging and inhaler technology. As such, pharmaceutical manufacturers must prioritize machine maintenance to maximize production capacity and ensure the consistent delivery of medicine dispensers for inhalation therapy.

Process Optimization and Production Efficiency in Aerosol Packaging

Process optimization and production efficiency in aerosol packaging is crucial for the manufacturing of metered dose valve assembly machines. By utilizing precision engineering and automation, pharmaceutical companies can ensure quality control and dosage accuracy in their inhaler production. Production standards are upheld through the use of high speed industrial machinery, increasing production capacity and quality assurance. Components are assembled using automated assembly equipment, allowing for efficient assembly line processes. This technology plays a significant role in the production of drug delivery devices, such as metered dose inhalers, and aids in inhalation therapy for patients in need of precise medication dosages.

Medicinal spray (aerosol) valve assembly line