Medicinal aluminum foil plays a crucial role in the pharmaceutical industry, ensuring medication safety and shelf life. The aluminum foil has excellent barrier properties, protecting drugs from moisture, light, and temperature changes. This sterile packaging is tamper evident, durable, and recyclable, meeting pharmaceutical industry standards. Medicinal aluminum foil is an innovative solution for personalized medicine packaging, enhancing medication freshness and transport efficiency. Upgrade to foil sealed medicine for eco friendly and hygienic drug packaging.

Understanding the Significance of Medicinal Aluminum Foil

Medicinal aluminum foil is an essential component in the pharmaceutical industry, used for various purposes such as blister packaging, pill packaging, and drug preservation. It plays a crucial role in providing sterile packaging for medicines, ensuring their storage and transportation in a safe and hygienic manner. The aluminum foil offers numerous benefits such as temperature control, moisture protection, and light resistance, which helps in preserving the freshness and effectiveness of the medications.

The use of aluminum foil in pharmaceuticals is in line with industry standards, as it provides a strong barrier against external factors that can affect the quality of the drugs. It is known for its durability, making it an ideal material for packaging medicines that require long shelf life. Additionally, aluminum foil is recyclable, making it an eco friendly option for pharmaceutical packaging.

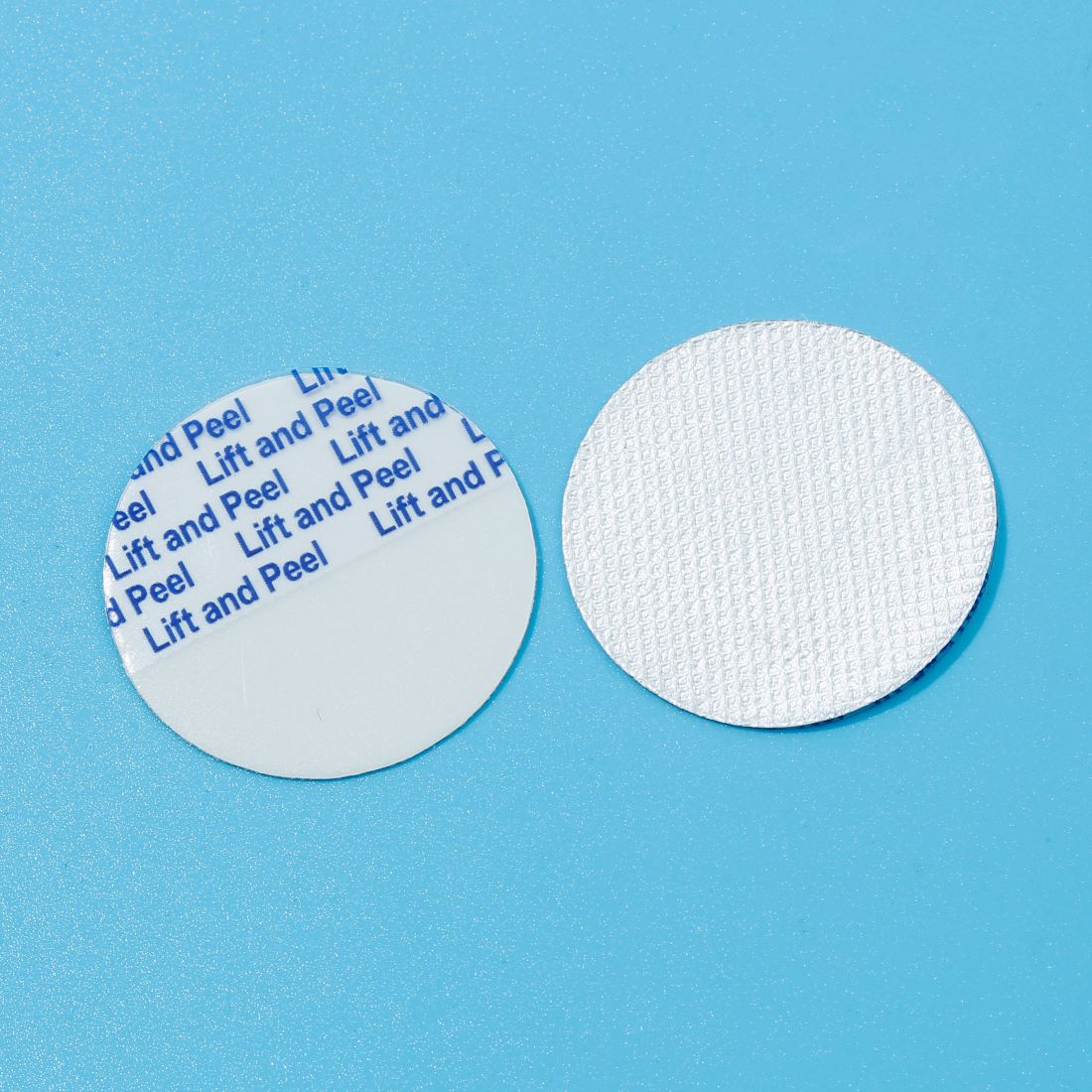

Foil sealed medicines offer tamper evident packaging, ensuring the safety and integrity of the medications. The production of medicinal aluminum foil involves innovative techniques to create personalized packaging solutions for different types of drugs. With its excellent barrier properties, aluminum foil continues to be a preferred choice for drug packaging materials in the pharmaceutical industry.

The Art of Medicine Packaging: An Overview of Aluminum Foil Uses

Medicinal aluminum foil plays a crucial role in pharmaceutical packaging, offering benefits such as drug preservation, light resistance, and temperature control. Aluminum foil is commonly used in blister packaging for pills, ensuring sterile and hygienic storage. Its barrier properties protect medicine from moisture and external elements, extending shelf life. The pharmaceutical industry adheres to strict standards for aluminum foil production to guarantee medication safety. This eco friendly material is recyclable and durable, making it ideal for medicine transportation. Aluminum foil innovation continues to drive personalized and tamper evident packaging solutions in the pharmaceutical sector.

Pharmaceutical Foil: Redefining Drug Preservation and Storage

Pharmaceutical foil plays a crucial role in redefining drug preservation and storage. Medicinal packaging using aluminum foil offers numerous benefits such as drug preservation, sterile packaging, and medicine storage. Aluminum foil is widely used in blister packaging and pill packaging to ensure medication safety and adhere to pharmaceutical industry standards. Its excellent barrier properties protect medicines from external factors, maintaining their freshness and extending shelf life. The foil’s light resistant properties help control temperature and provide moisture protection, making it ideal for medicine transportation. Additionally, aluminum foil is durable, hygienic, and recyclable, making it an eco friendly choice for personalized and tamper evident packaging in the pharmaceutical industry. In conclusion, pharmaceutical foil is an innovative solution for enhancing medication safety, storage, and transportation.

Aluminum Foil Benefits: The Backbone of Hygienic Pharmaceutical Packaging

Aluminum foil in pharmaceutical packaging plays a crucial role in ensuring the safety and effectiveness of medicinal products. Pharmaceutical foil, often used in blister packaging and pill packaging, helps to preserve drugs by providing a sterile and hygienic environment. The aluminum barrier properties of foil sealed medicine protect drugs from external elements, such as moisture, light, and temperature changes, which can affect medicine freshness and effectiveness. Additionally, aluminum foil in pharmaceuticals is a durable material that can withstand the rigors of medicine transportation, ensuring that the medication reaches the patient in perfect condition. Moreover, aluminum foil is recyclable, making it an eco friendly option for personalized medicine packaging. Overall, the innovation of medicinal aluminum foil production has resulted in tamper evident packaging that meets pharmaceutical industry standards and extends the shelf life of medications during foil based drug transport.

Aluminum foil