In the healthcare industry, the quality and safety of intravenous (IV) fluids are paramount. IV fluids are critical in patient care, used to deliver medications, maintain hydration, and provide essential nutrients. Any contamination or defect in these fluids can lead to severe health risks. To ensure the highest standards of quality, manufacturers employ sophisticated inspection systems. The advent of AI technology has revolutionized these systems, making them more accurate, efficient, and reliable. This article explores how AI-enhanced light inspection machines are transforming the inspection process for IV fluids.

The Importance of IV Fluid Inspection

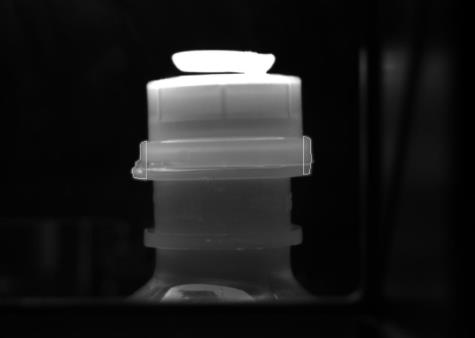

IV fluids, administered directly into a patient’s bloodstream, must be free from contaminants and defects. Contaminants like particulate matter, fibers, or microbial impurities can cause infections, allergic reactions, or other adverse effects. Similarly, defects in the container, such as cracks, leaks, or improper seals, can compromise the sterility and integrity of the IV fluid. Traditional inspection methods, often manual, are labor-intensive and prone to human error. Automated light inspection machines, especially those integrated with AI technology, offer a more robust solution.

How Light Inspection Machines Work

Light inspection machines utilize various light sources to illuminate IV fluid containers, allowing for the detection of contaminants and defects. These machines typically consist of an inspection chamber, lighting system, cameras, sensors, conveyor system, control unit, and a rejection mechanism.

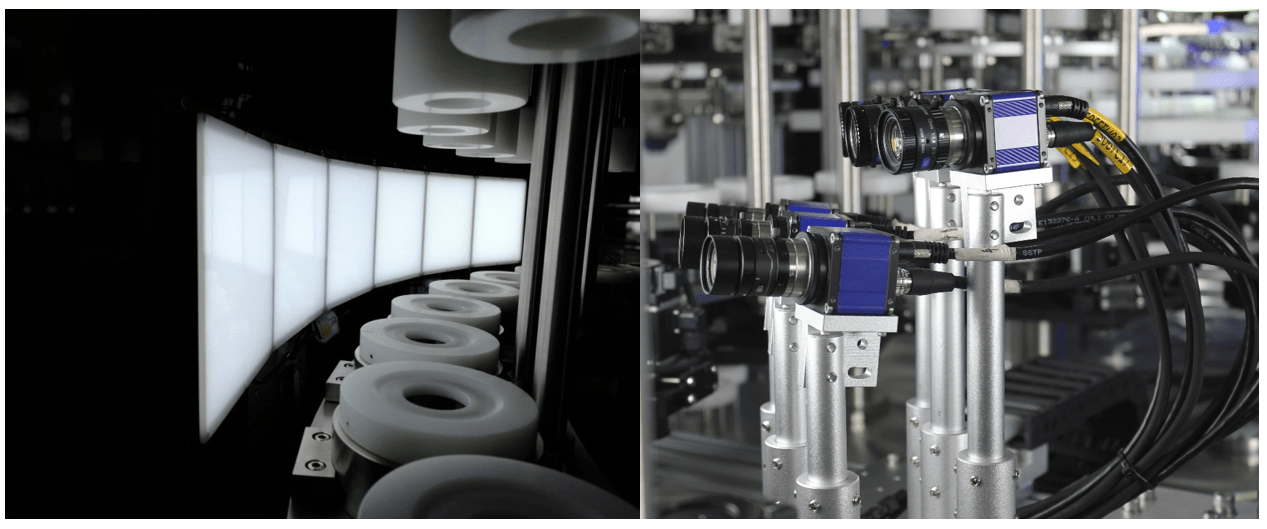

- Inspection Chamber: The area where IV fluid containers are placed for inspection. The chamber is designed to provide optimal lighting conditions.

- Lighting System: Employs different types of light (e.g., LED, fluorescent) to enhance visibility of particulates and defects.

- Cameras and Sensors: Capture high-resolution images or video of the IV fluid containers from multiple angles.

- Conveyor System: Transports the containers through the inspection chamber at controlled speeds.

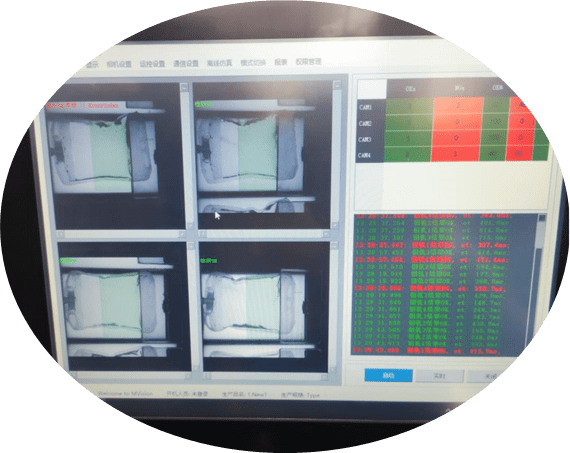

- Control Unit: Manages the operation of the machine, including lighting, cameras, and conveyor system, and processes the data.

- Rejection Mechanism: Automatically removes defective containers from the production line.

Integrating AI Technology

AI technology significantly enhances the capabilities of light inspection machines. By employing advanced image processing, machine learning, and data analytics, AI-driven systems can detect even the smallest defects and contaminants with greater accuracy and speed.

Advanced Image Processing

AI algorithms, particularly those based on deep learning and computer vision, excel in analyzing images. These algorithms can identify patterns and anomalies that traditional methods might miss. Convolutional neural networks (CNNs), a type of deep learning model, are particularly effective in image recognition tasks. They can be trained to recognize various types of defects and contaminants in IV fluid containers.

Anomaly Detection

Machine learning models can be trained on large datasets of images, including both normal and defective samples. Once trained, these models can quickly identify deviations from the norm. This capability is crucial for detecting rare or unexpected defects that might not be captured by rule-based inspection systems.

Continuous Learning and Improvement

One of the most significant advantages of AI systems is their ability to learn and improve over time. As more data is collected and analyzed, AI models become more accurate and efficient. This continuous learning capability ensures that the inspection process remains effective and up-to-date with the latest quality control standards.

Data Analytics and Reporting

AI-enhanced inspection machines can analyze vast amounts of data to provide valuable insights into the production process. Advanced analytics can identify trends, recurring issues, and potential areas for improvement. This information is crucial for proactive quality control and can help in predictive maintenance of the inspection equipment.

Implementation Steps

Integrating AI into light inspection machines involves several key steps:

- Data Collection and Training: Gather a large dataset of images from previous inspections, including examples of both acceptable and defective IV fluids. This data is used to train machine learning models.

- Algorithm Development: Develop and refine AI algorithms to process the images and detect defects. Convolutional neural networks (CNNs) and other deep learning techniques are commonly used.

- System Integration: Integrate the AI models with existing inspection machine hardware, ensuring seamless communication between cameras, sensors, and the AI software.

- Testing and Validation: Rigorously test the AI-enhanced system to ensure it meets quality and safety standards. Validate its performance with a variety of IV fluid containers and defect types.

- Deployment and Monitoring: Deploy the AI-enhanced machine in a production environment and continuously monitor its performance. Adjustments can be made based on feedback and new data.

Benefits of AI-Enhanced Inspection Machines

AI-enhanced light inspection machines offer several significant benefits:

- Increased Accuracy: AI systems detect defects with higher precision, reducing false positives and false negatives.

- Improved Consistency: AI ensures consistent inspection quality, eliminating variability caused by human inspectors.

- Scalability: AI systems can handle higher volumes of inspections without a proportional increase in labor costs.

- Cost Efficiency: While the initial investment in AI technology may be substantial, the long-term savings from reduced labor costs and improved defect detection justify the expense.

Challenges and Considerations

Despite the advantages, integrating AI into inspection systems presents challenges:

- Initial Setup and Training: Developing and training AI models require substantial initial investment in time, data, and computational resources.

- Regulatory Compliance: Ensure the AI-enhanced inspection system complies with regulatory standards for medical devices and pharmaceutical manufacturing.

- Maintenance and Updates: Regular maintenance and updates are necessary to keep the AI system functioning optimally and adapting to new defect types or production changes.

Case Study: Successful Implementation

A leading pharmaceutical manufacturer integrated AI technology into their light inspection machines for IV fluids. By using a large dataset of historical inspection images, they trained a convolutional neural network (CNN) to detect various defects, including particulate matter, container cracks, and improper seals.

Post-implementation, the AI-enhanced system demonstrated a significant increase in detection accuracy, reducing false positives by 20% and false negatives by 25%. The automated system also handled a 30% higher volume of inspections, translating to increased productivity. Moreover, data analytics provided insights that led to process improvements, further enhancing product quality.

Future Prospects

The future of AI in light inspection machines looks promising. Advancements in AI and machine learning algorithms will continue to enhance the accuracy and efficiency of inspection systems. Additionally, integrating other technologies like the Internet of Things (IoT) and blockchain can further improve traceability and transparency in the production process.

Conclusion

AI-enhanced light inspection machines represent a significant advancement in ensuring the quality and safety of IV fluids. By leveraging AI technology, manufacturers can achieve higher accuracy, efficiency, and consistency in the inspection process, ultimately safeguarding patient health. As AI continues to evolve, its integration into inspection systems will become increasingly sophisticated, setting new standards for quality control in the healthcare industry.

Inspection Machine