Introduction:

In the realm of pharmaceutical manufacturing, the choice of packaging plays a critical role in ensuring product safety and efficacy. One innovative solution gaining popularity is the use of IV PP bottle solutions. These bottles, made from polypropylene (PP), offer numerous advantages for storing and delivering intravenous (IV) fluids and medications. Let’s explore how incorporating IV PP bottle solutions into pharmaceutical manufacturing processes can revolutionize the industry.

Understanding IV PP Bottle Solutions:

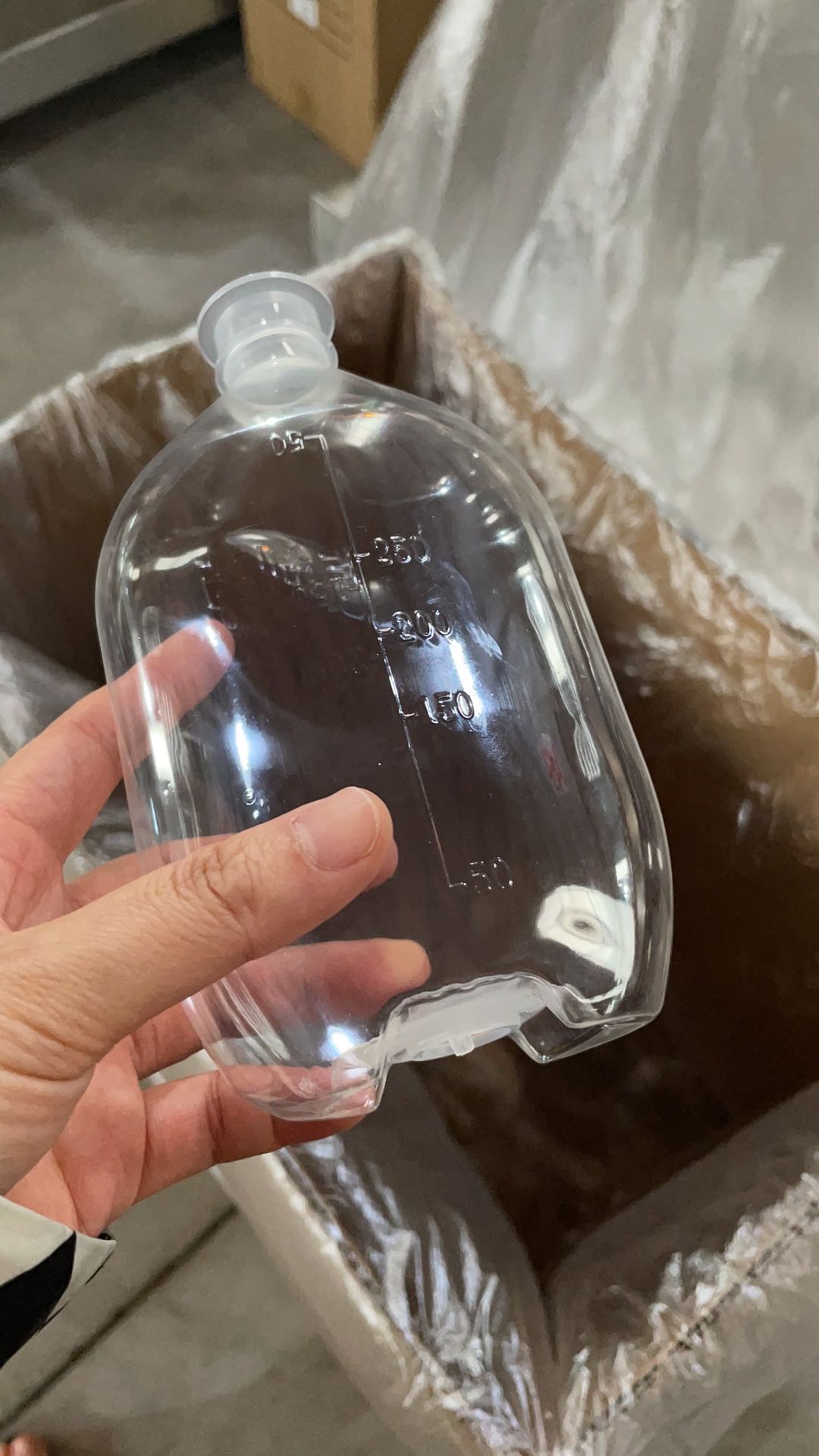

Before we delve into the benefits, let’s understand what IV PP bottle solutions are. IV PP bottles are containers made from polypropylene, a durable and lightweight plastic material. These bottles are specifically designed to store and dispense IV fluids and medications safely and efficiently. With their versatility and reliability, IV PP bottle solutions are increasingly becoming the packaging option of choice for pharmaceutical manufacturers worldwide.

Advantages of IV PP Bottle Solutions:

Durability: IV PP bottles are known for their robustness, offering superior protection against breakage and leakage compared to traditional glass bottles.

Lightweight: Being lightweight, IV PP bottles are easier to handle and transport, reducing the risk of accidents and injuries in pharmaceutical manufacturing facilities.

Transparency: The clarity of PP material allows for easy visual inspection of the contents, ensuring quality control and minimizing errors during production.

Chemical Resistance: PP is highly resistant to chemicals, making IV PP bottles suitable for storing a wide range of IV fluids and medications without risk of contamination.

Cost-Effectiveness: IV PP bottles are more cost-effective than glass alternatives, offering significant savings in manufacturing and transportation costs.

Incorporating IV PP Bottle Solutions into Manufacturing Processes:

Integrating IV PP bottle solutions into pharmaceutical manufacturing processes is a straightforward and beneficial endeavor. Manufacturers can easily transition from traditional glass bottles to IV PP bottles with minimal disruption to operations. Additionally, suppliers of pharmaceutical manufacturing machines offer specialized equipment designed to accommodate IV PP bottle solutions, further facilitating the adoption of this innovative packaging option.

Transitioning to IV PP Bottle Solutions:

Transitioning to IV PP bottle solutions is a proactive step towards enhancing efficiency and safety in pharmaceutical manufacturing. By partnering with suppliers who offer IV PP-compatible machinery and providing comprehensive training to staff, manufacturers can seamlessly integrate IV PP bottle solutions into their operations. The transition not only improves product quality and safety but also demonstrates a commitment to innovation and sustainability in the pharmaceutical industry.

Conclusion:

In conclusion, IV PP bottle solutions represent a game-changing advancement in pharmaceutical packaging. With their durability, lightweight design, transparency, chemical resistance, and cost-effectiveness, IV PP bottles offer numerous advantages for storing and delivering IV fluids and medications. By incorporating IV PP bottle solutions into manufacturing processes, pharmaceutical companies can enhance efficiency, improve product safety, and stay ahead of the curve in an ever-evolving industry.

IV FLUID SOLUTION LINE