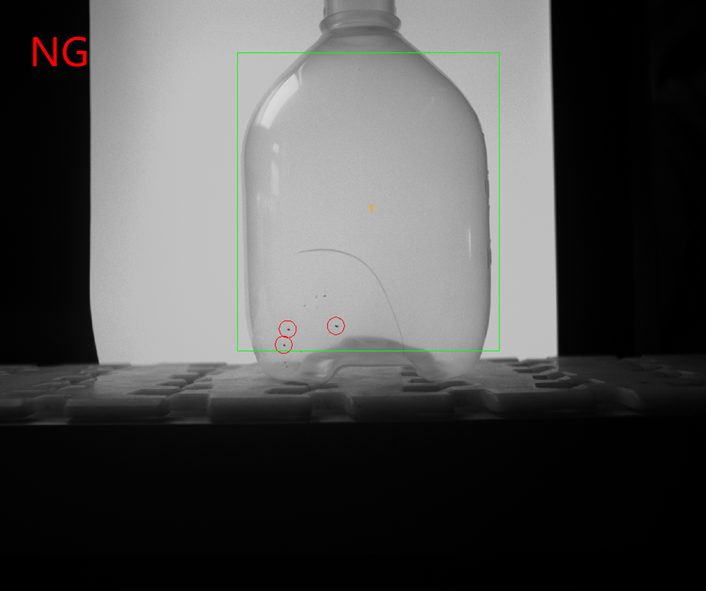

An IV bottle inspection machine plays a crucial role in enhancing pharmaceutical production by providing advanced features and benefits. The automated inspection capabilities ensure quality assurance throughout the manufacturing process. The machine’s accuracy in defect detection and high speed inspection contribute to improved efficiency in production. It also aids in contamination prevention and sterile processing, aligning with pharmaceutical compliance standards.

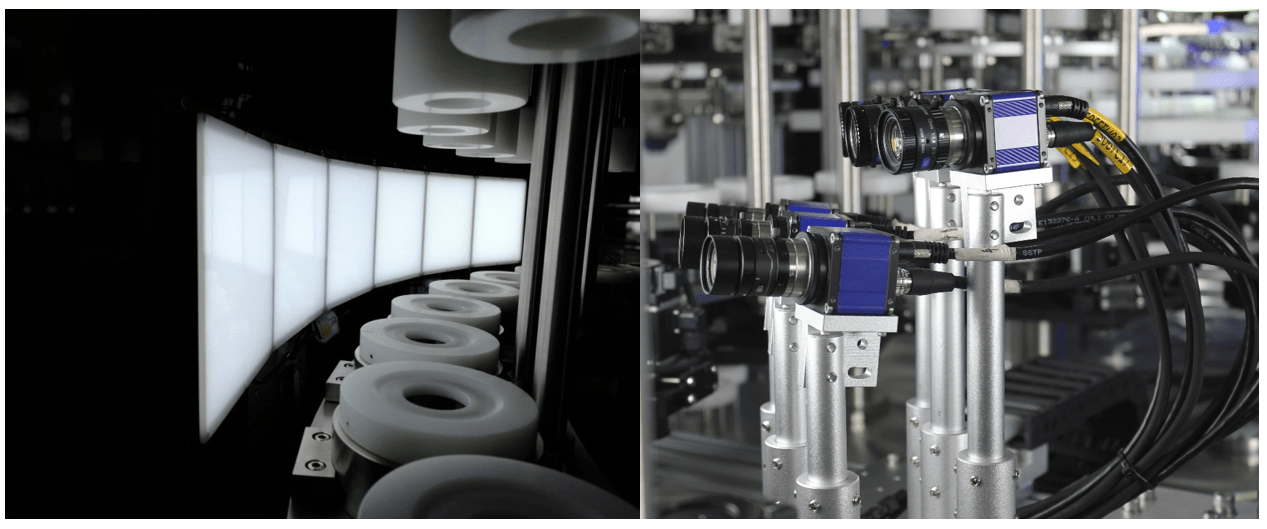

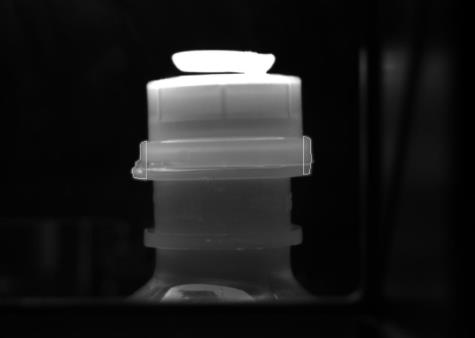

The advanced technology incorporated in IV bottle inspection machines allows for increased throughput capacity while maintaining a user friendly interface for operators. Safety compliance is a key feature, ensuring a cost effective operation with precision inspection and reliable performance. The machine optimizes production by conducting bottle integrity checks and ensuring product consistency through real time monitoring.

Easy maintenance of the machine reduces wastage and operational speed, while software capabilities enhance functionality. The durability of the machine, coupled with its compact design, makes it a valuable asset in pharmaceutical production. Additionally, the ability to inspect multi size bottles and customize settings further enhances its usefulness in the industry.

Understanding the Role of IV Bottle Inspection Machine in Pharmaceutical Production

The IV bottle inspection machine plays a crucial role in pharmaceutical production by ensuring automated inspection for quality assurance. This advanced technology helps in detecting defects, preventing contamination, and maintaining sterile processing. With high speed inspection and precise defect detection, the machine enhances manufacturing efficiency while optimizing production. The user friendly interface and customizable settings make it easy to operate, ensuring safety compliance and pharmaceutical standards. Its reliability, durability, and compact design contribute to cost effective operation, reduced wastage, and product consistency. The machine’s throughput capacity, real time monitoring, easy maintenance, and multi size bottle inspection capabilities further improve operational speed and efficiency in pharmaceutical manufacturing.

Key Features of IV Bottle Inspection Machines: A Deep Dive

IV bottle inspection machines are vital components in pharmaceutical production, ensuring quality assurance and manufacturing efficiency. These machines offer a wide range of features, including automated inspection for machine accuracy and defect detection. They are designed for high speed inspection to prevent contamination and uphold sterile processing standards. With advanced technology, IV bottle inspection machines can handle large throughput capacities while providing a user friendly interface for operators.

Safety compliance is a top priority, with cost effective operation and precision inspection capabilities. These machines offer reliable performance to meet pharmaceutical compliance standards and optimize production processes. They conduct bottle integrity checks to maintain product consistency and provide real time monitoring for quality control. Maintenance is easy, reducing wastage and improving operational speed.

Additionally, IV bottle inspection machines are equipped with software capabilities to enhance machine durability and efficiency. Their compact design allows for multi size bottle inspection with customizable settings for various production needs. Overall, these machines play a crucial role in ensuring pharmaceutical products meet the highest quality standards.

To learn more about IV bottle inspection machines, visit the Wikipedia page here.

The Benefits of Implementing IV Bottle Inspection Machines in Manufacturing Processes

Implementing IV bottle inspection machines in manufacturing processes provides numerous benefits, such as automated inspection for quality assurance in pharmaceutical production. These machines offer manufacturing efficiency with high speed inspection and precise defect detection. By preventing contamination, ensuring sterile processing, and utilizing advanced technology, IV bottle inspection machines optimize production. The throughput capacity, user friendly interface, and compliance with safety regulations make them cost effective and reliable for pharmaceutical compliance. Additionally, these machines enhance bottle integrity checks, maintain product consistency, and allow for real time monitoring and easy maintenance. By reducing wastage and increasing operational speed, IV bottle inspection machines contribute to production optimization. Their software capabilities, durability, compact design, and ability to inspect multi sized bottles with customizable settings make them essential for pharmaceutical manufacturers.

Investing in IV Bottle Inspection Machines: A Cost Effective Decision for the Future of Pharmaceutical Production

Investing in IV Bottle Inspection Machines is a cost effective decision for the future of pharmaceutical production. IV bottle inspection machines offer automated inspection, ensuring quality assurance in pharmaceutical production. These machines enhance manufacturing efficiency through their high speed inspection capabilities and accurate defect detection. By preventing contamination, they contribute to sterile processing, meeting advanced technology standards in pharmaceutical compliance. With a high throughput capacity and user friendly interface, IV bottle inspection machines optimize production processes. They offer cost effective operation, precise inspection, and reliable performance, ensuring bottle integrity checks and product consistency through real time monitoring. Easy maintenance, reduced wastage, operational speed, and customizable settings make these machines a valuable asset in pharmaceutical production.

Visual Inspection Machine For IV solution

Deutsch

Deutsch हिन्दी

हिन्दी 日本語

日本語 한국어

한국어 Монгол

Монгол Português

Português Русский

Русский Español

Español தமிழ்

தமிழ் Türkçe

Türkçe Українська

Українська Tiếng Việt

Tiếng Việt