An IV Bottle Cap Assembly Machine is a crucial piece of equipment in the pharmaceutical industry for the production of IV bottle caps. This automated machinery is specifically designed for the sterile assembly of caps for infusion bottles. The IV cap assembly process involves the use of healthcare equipment to ensure the safe and efficient manufacturing of IV bottles. The machinery is capable of efficiently assembling caps made of various materials such as rubber and plastic. IV bottle cap assembly automation plays a significant role in pharmaceutical manufacturing, ensuring the production of sterile caps for medical use. This equipment is essential for the seamless production of infusion bottles, contributing to the overall healthcare industry by providing high quality IV bottle production equipment.

Introduction to IV Bottle Cap Production and Its Importance in Healthcare

IV Bottle Cap Production is a crucial step in the manufacturing process of healthcare equipment. The use of automated IV cap machinery ensures efficient and sterile equipment assembly for infusion bottles. Pharmaceutical machinery plays a vital role in the cap assembly process, utilizing cap material such as rubber and plastic. This automated cap assembly not only streamlines the production process but also ensures the quality and safety of the final product. IV bottle cap equipment is essential in the healthcare industry as it contributes to the manufacturing of sterile caps for medical bottles, including infusion bottle manufacturing. The IV cap assembly automation in pharmaceutical manufacturing plays a significant role in producing quality healthcare equipment for patients worldwide.

Exploring the Assembly machine for IV Cap Production

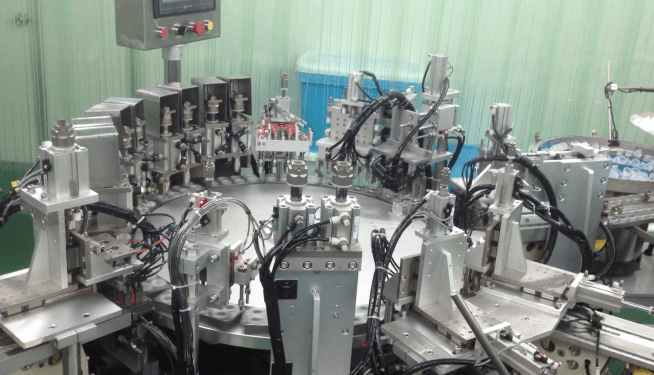

The assembly machine for IV cap production is a crucial piece of equipment in the pharmaceutical industry. It plays a vital role in the production of IV bottle caps, ensuring the sterile and efficient assembly of caps for infusion bottles. The IV cap machinery is designed to automate the cap assembly process, providing a seamless and precise operation for healthcare equipment production.

The automated cap assembly process involves the use of specialized pharmaceutical machinery to manufacture IV bottle caps. These machines are equipped to handle different cap materials such as rubber and plastic, ensuring a high quality finish for each cap produced. The infusion bottle cap machine is essential for the efficient manufacturing of IV bottle caps, meeting the strict standards required for medical bottle cap production.

In the pharmaceutical manufacturing industry, IV cap assembly automation is key to streamlining the production process and ensuring consistent quality in the final product. The sterile cap assembly provided by these machines is crucial for maintaining the integrity of the IV bottle production equipment, meeting the stringent requirements for healthcare settings.

Overall, the assembly machine for IV cap production plays a vital role in the manufacturing process of infusion bottles, providing a reliable and efficient solution for pharmaceutical companies. Its precision and automation capabilities make it an essential piece of equipment for the production of IV bottle caps, meeting the high standards required in the healthcare industry.

Detailed Breakdown of the IV Bottle Cap Assembly Process

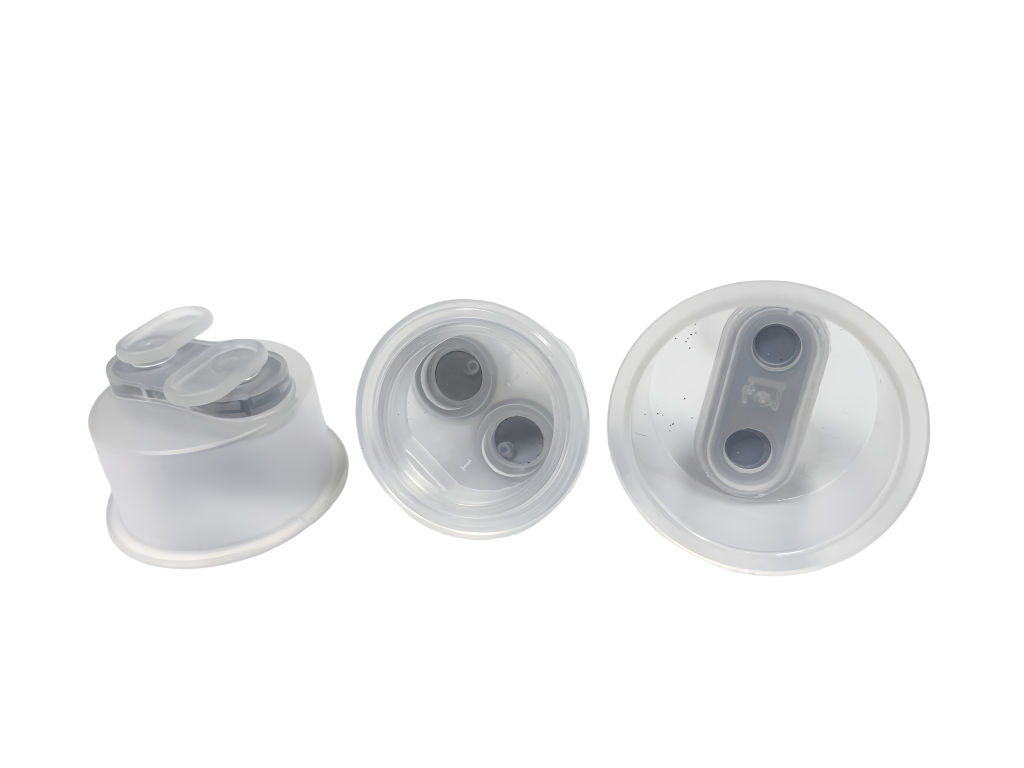

The IV bottle cap assembly process involves a series of steps to ensure efficient and precise production of IV bottle caps. The process begins with the IV cap material, which can be made of rubber or plastic, being fed into the assembly machine. The assembly machine then assembles the cap with the necessary components to create a sterile cap suitable for use in healthcare settings.

The pharmaceutical machinery used in the cap assembly process is designed to automate the production of IV bottle caps, ensuring consistent quality and reducing the risk of contamination. Healthcare equipment production relies on the IV cap machinery to manufacture caps that meet strict industry standards for safety and functionality.

IV bottle manufacturing involves the infusion cap assembly, where the cap is securely attached to the bottle to prevent leakage or tampering. Sterile cap assembly is essential in ensuring that the IV bottles meet sterile requirements for medical use.

The IV cap assembly automation streamlines the production process, increasing efficiency and reducing production costs. Pharmaceutical manufacturing companies rely on this automation to produce a high volume of medical bottle caps quickly and accurately.

Infusion bottle manufacturing requires specialized IV bottle production equipment to create bottles that are durable and leak proof. Cap material plays a crucial role in the quality of the final product, with rubber and plastic caps being the most commonly used materials.

Overall, the IV bottle cap assembly process is a critical step in the production of healthcare equipment, ensuring that medical professionals have access to sterile and reliable IV bottles for patient care.

Materials Utilized in IV Cap and Bottle Production – From Rubber to Plastic

Rubber and plastic are the two main materials utilized in the production of IV bottle caps and bottles. Rubber caps are commonly used in healthcare equipment production due to their flexibility and ability to create a secure seal. On the other hand, plastic caps are lightweight and cost effective, making them ideal for mass production in pharmaceutical manufacturing. The assembly process for these caps involves sterile equipment assembly to ensure the safety and cleanliness of the final product. Automated cap assembly machines play a crucial role in the efficient production of IV bottle caps, increasing productivity and reducing manual labor. Overall, the choice of material, whether rubber or plastic, depends on the specific requirements of the healthcare industry and the desired properties of the final product.

Cap Assembly Machine