Vision Inspection Machine for IV bag

Machine description :

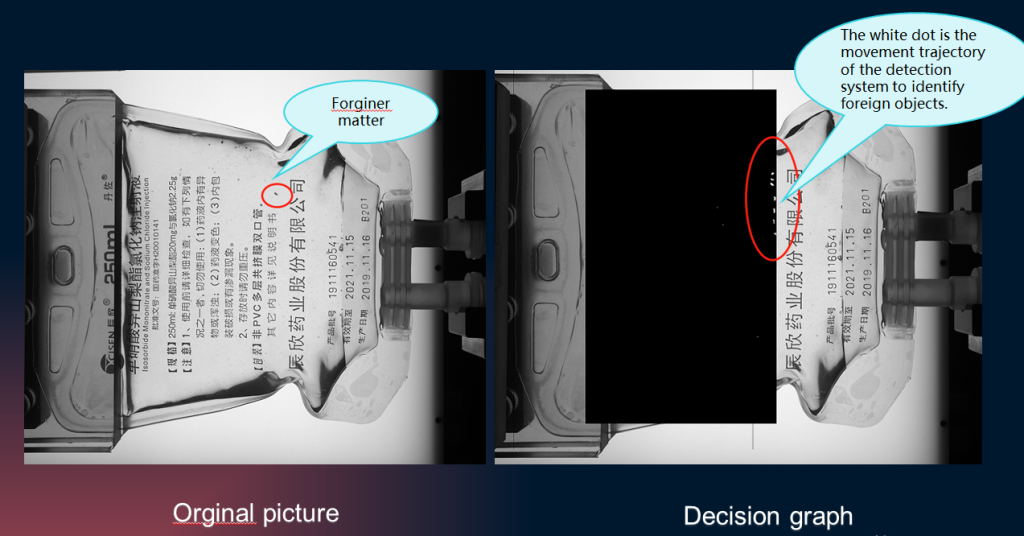

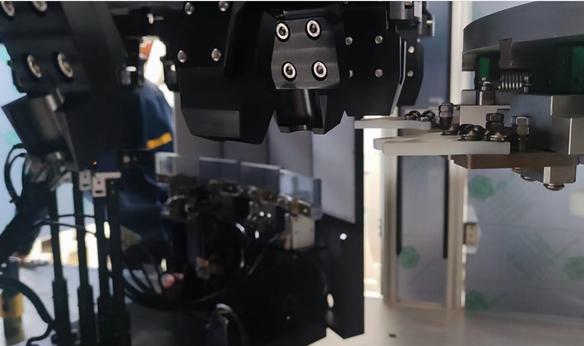

The main function of the soft bag light/vision inspection machine is to detect visible insoluble particle defects in soft bags for LVI, and at the same time detect appearance defects of such containers themselves. The equipment’s inspection software uses the machine’s own light source system and high-resolution industrial cameras to identify defects in the products and automatically eliminate corresponding defective products.

Feature :

- Software: The Italian special large infusion particle detection software E-scan and the independently developed bottom detection software are used. The two are effectively compatible and work closely together to form a perfect software system specifically for particle detection in large infusion soft bags.

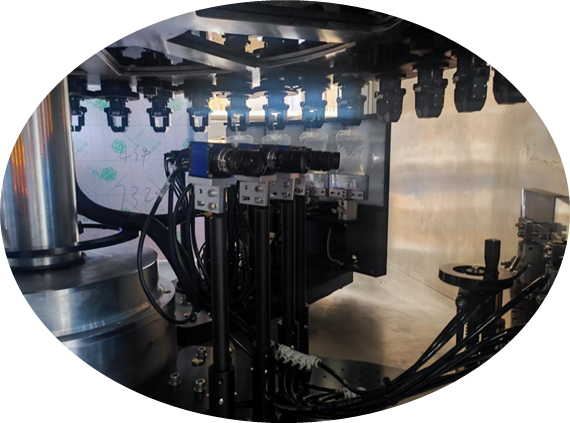

- Hardware: It adopts the world’s top-grade CCD industrial camera, which is characterized by high detection accuracy, long life and high stability.

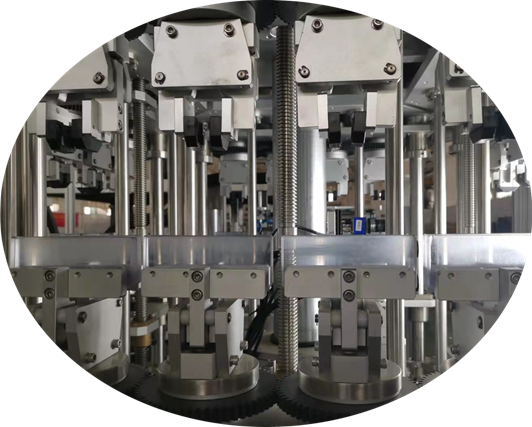

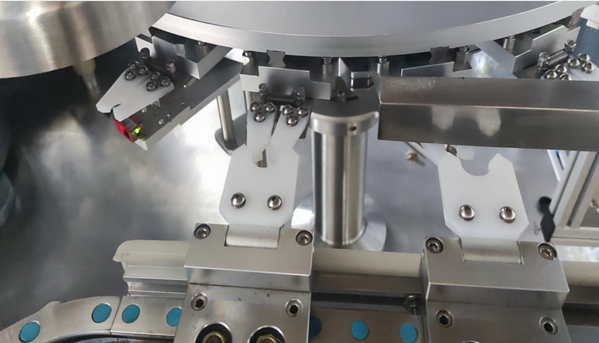

- Machinery: Specially designed for the characteristics of soft bags, from the irregularity of transmission, high-speed robots are used to organize and position them, so that the product can be stably transported into the machine. Through servo rotation, it drives the movement of particles in the liquid, and through high-speed The camera continuously takes pictures to find foreign objects, and uses computer calculations to make judgments about the product.

Inspection content :

- Detection of sunk foreign objects: including black spots, metal shavings, etc.

- Detection of foreign objects in liquid: including color blocks, hair, mosquitoes, fibers, etc.

- Bag body appearance inspection; including double port gasket breakage, skew greater than 30 degrees, flash, printing absence etc.

Machine Parameter:

- Detection speed: max speed 12000 bags/hour;

- Applicable specifications: 50ml-500mI

- Detection accuracy: ≥50um;

| DR000 Light isnpection machine parametre | ||

| General | model | YFR2H200 |

| Speed | 12000bags/hour | |

| Bag volume | 50ml、100ml、250ml、500ml | |

| software | VISION | |

| Electrical parameters | Voltage | 3 phases + neutral + ground 380V 50Hz |

| Auxiliary power | 24VDC | |

| Power | 17Kw | |

| Nominal current | 45A | |

| Air source | Compressed air | 6 Bar ~ 8 Bar (kg) |

| Weight | 整机(主机+加进出瓶传送带) | 2 TONS |

| Dimension | L xWx H(mm) | 6700*2300*2520 |

- Mechanical mechanism: All parts in contact with the product are made of 304 stainless steel and comply with GMP standards for medical machinery.

- Image acquisition: Using German MV cameras and domestic top light sources, with professional algorithms from Italian software, which greatly enhances the competitiveness of the product.

- Control system: Adopt Japanese Omron automation system