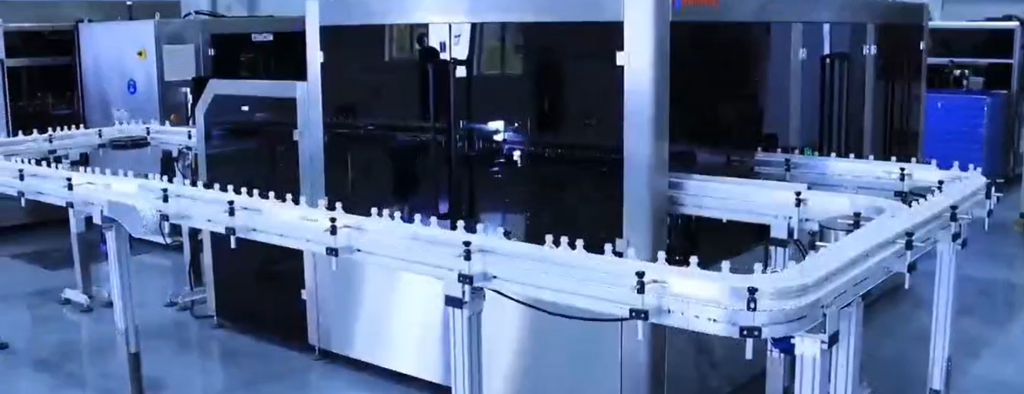

Light Inspection machine for IV PP bottles , glass bottles ,IV bag

This inspection machine can be applied in preform inspection , glass bottles , PP bottles ,IV bag inspection.

Description:

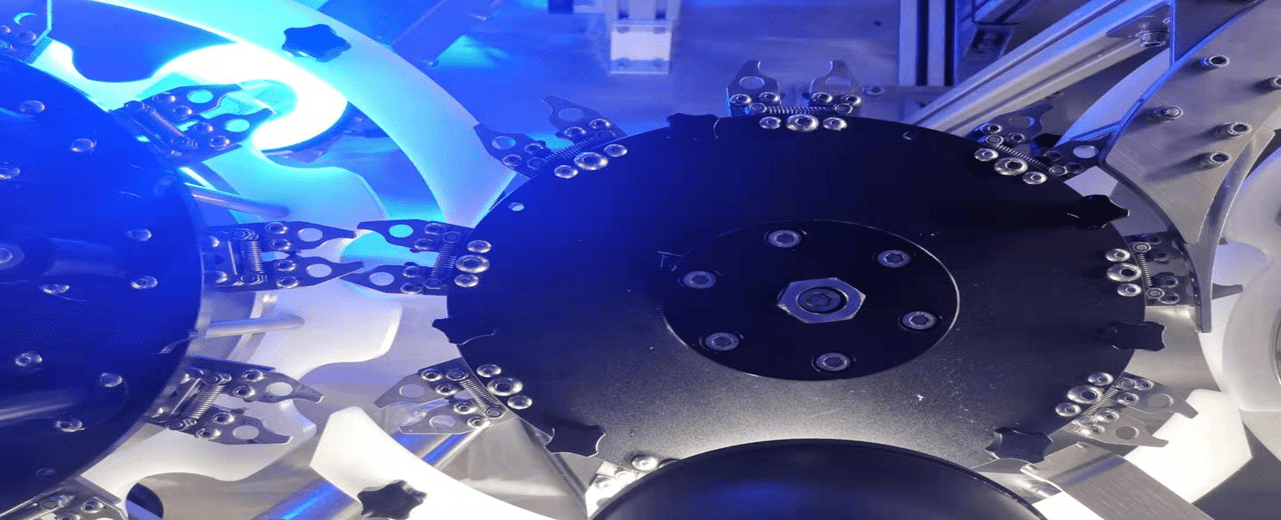

The screw/dial feeds the bottles at intervals

- Through the transfer between star wheels, the inspected bottles are sent to each appearance inspection station in sequence.

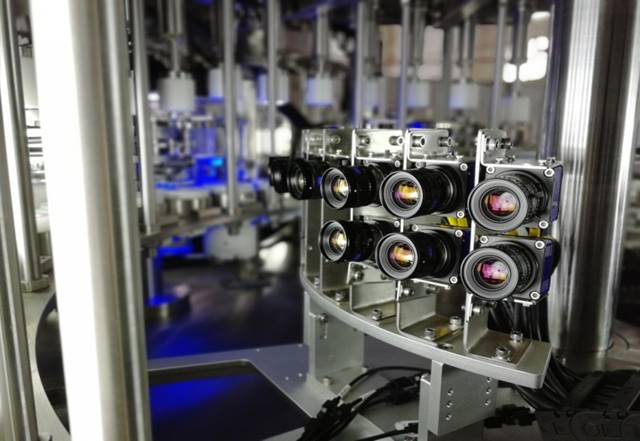

- After the bottle under inspection is transported to the particle detection turntable, the bottle rotation is driven by the rotating bottle motor, and the rotation stops after the bottle enters the detection area, and the high-speed camera collects pictures of the bottle.

- After completing the picture collection of all inspection stations, the visual system will identify and determine whether the inspected bottle is defective, and send the result to the PLC. If it is identified as an unqualified bottle, the PLC will control the action of the rejection mechanism. Remove defective products

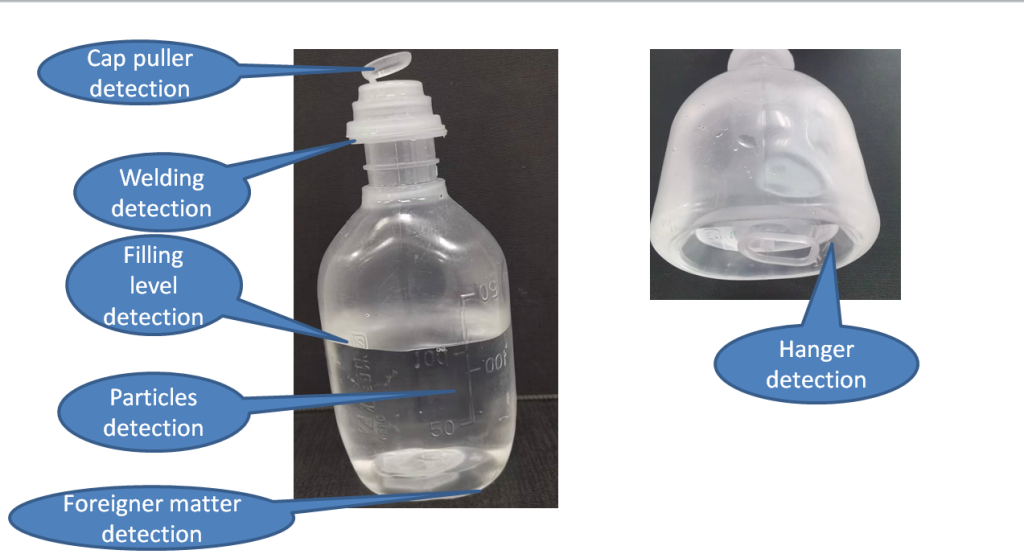

Detection content:

- Foreign matter in the liquid (color spots, black spots, fibers, glass chips, mosquitoes, hair, etc.)

- Pull tab defect detection

- Lifting ring defect detection

- Loading quantity detection

- Bottle cap detection

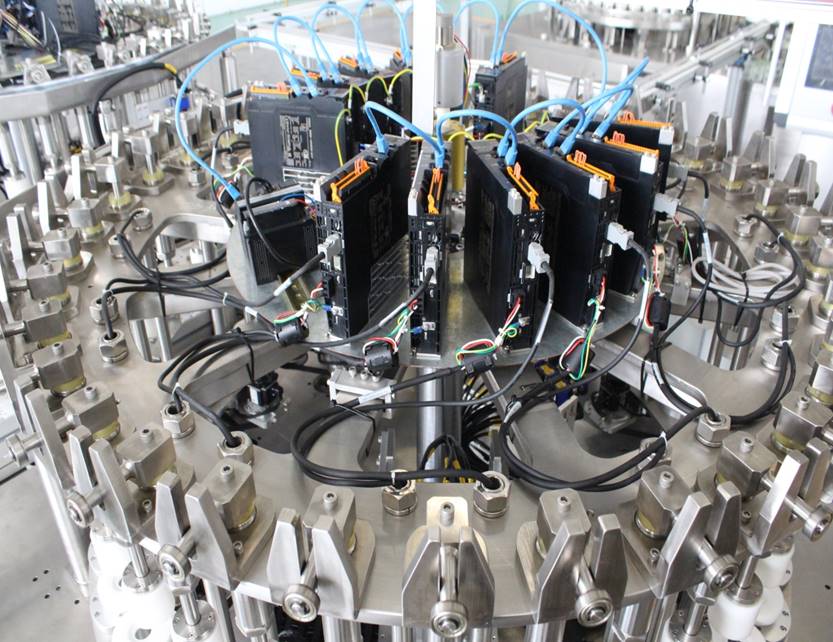

Main configuration:

- Multiple industrial computers (Taiwan Advantech);

- High frame rate industrial camera (Basle, Germany);

- Customized LED light source;

- Omron NJ series high-performance PLC;

- Omron/Inovance servo motor;

Machine inspection capacity :

200-450 bottles/min , customize on you products and requirement

can detect visual particulate size : ≥50um

Machine pictures: