In medical consumables manufacturing, the assembly of crucial medical devices like dialysis catheters demands meticulous attention to detail and adherence to stringent standards. Assembling a dialysis catheter requires a thorough understanding of its components, functions, and precise assembly techniques. This comprehensive guide delves into the intricate process of making a dialysis catheter, highlighting essential steps and considerations.

Understanding the Dialysis Catheter

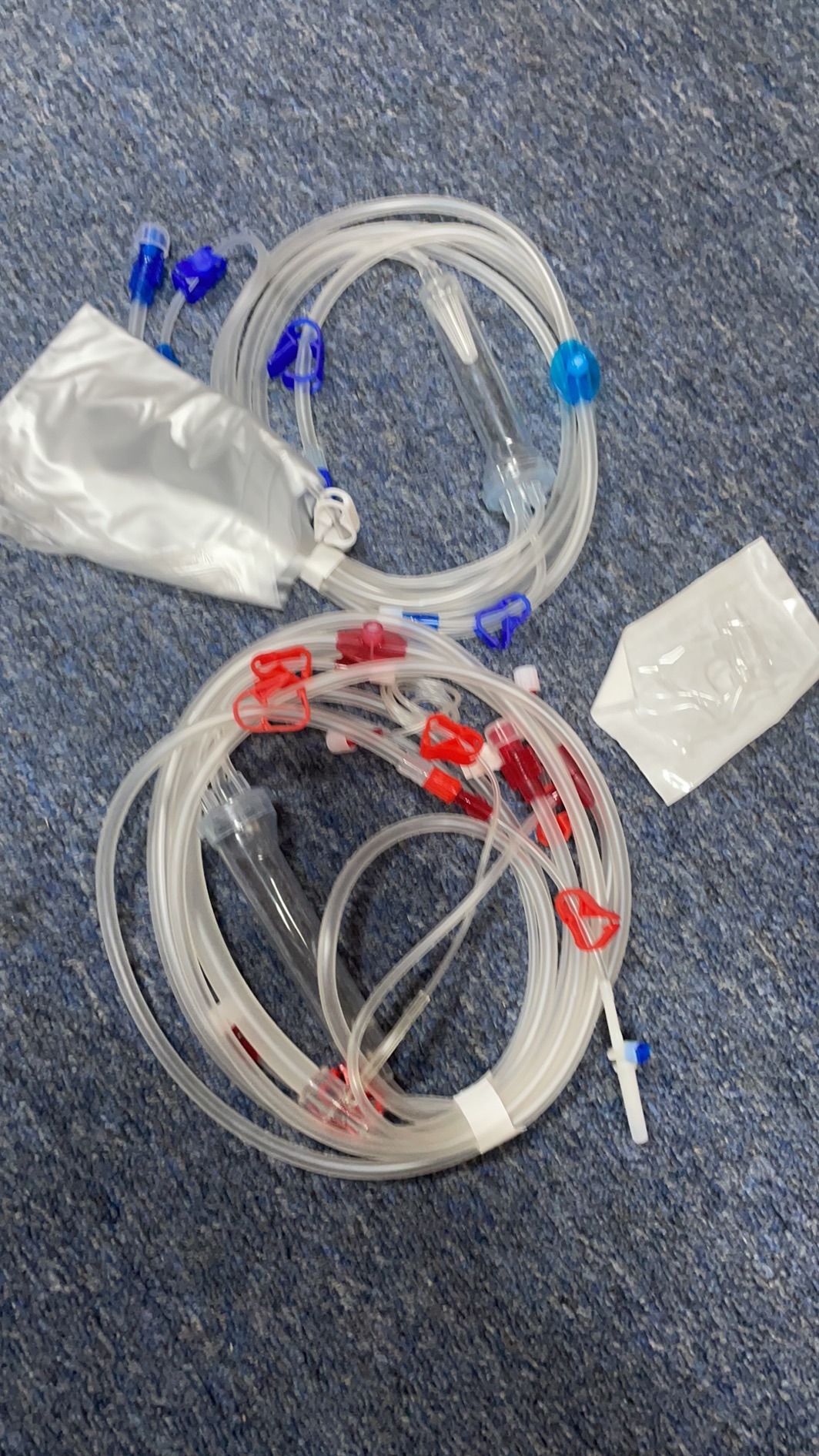

Before diving into the assembly process, it’s vital to grasp the anatomy and purpose of a dialysis catheter. A dialysis catheter is a medical device that provides access to the bloodstream for hemodialysis treatment, a procedure vital for patients with kidney failure. Typically, a dialysis catheter consists of several components, including:

Catheter Body: The main tubing through which blood flows.

Lumens: Channels within the catheter body for blood withdrawal and return.

Distal and Proximal Ends: The distal end enters the vein, while the proximal end connects to the dialysis machine.

Cuffs: Cylindrical structures on the catheter body that promote tissue ingrowth for stability.

Injection Ports: Additional ports for medication administration or blood sampling.

Preparation and Safety Measures

Before commencing the assembly process, ensure a sterile working environment and gather all necessary components and tools. Following stringent hygiene protocols is imperative to prevent contamination and ensure patient safety. Appropriate personal protective equipment (PPE), such as gloves and masks, must be used to maintain aseptic conditions.

Step-by-Step Assembly Process

Inspect Components: Thoroughly examine each component of the dialysis catheter kit to ensure integrity and cleanliness. Check for any signs of damage or defects that could compromise performance.

Prepare Catheter Body: Prepare the catheter body, ensuring it is free from kinks or twists. Trim the catheter to the desired length, considering factors such as patient anatomy and insertion site.

Attach Lumens: Carefully attach the lumens to the designated ports on the catheter body, ensuring secure connections without any leaks. Verify proper alignment to facilitate smooth blood flow during dialysis.

Secure Cuffs: Slide the cuffs onto the catheter body at predetermined positions, ensuring they are evenly spaced and aligned. Apply gentle pressure to secure the cuffs, promoting tissue ingrowth for long-term stability.

Connect Proximal End: Affix the proximal end of the catheter to the dialysis machine or connector, ensuring a secure and airtight connection. Perform leak tests to confirm integrity and prevent potential complications during dialysis.

Final Inspection: Conduct a final inspection of the assembled catheter, checking for proper alignment, secure connections, and absence of defects. Verify that all components meet quality standards and regulatory requirements.

Quality Assurance and Compliance

Throughout the assembly process, prioritize quality assurance measures to uphold product efficacy and patient safety. Implement comprehensive quality control protocols, including visual inspections, functional testing, and documentation of assembly procedures. Adhere to relevant regulatory guidelines and industry standards to ensure compliance and mitigate risks associated with medical device manufacturing.

Conclusion

Assembling a dialysis catheter requires precision, attention to detail, and adherence to stringent quality standards. By following the step-by-step process outlined in this guide, manufacturers can ensure the production of reliable and effective medical devices essential for hemodialysis treatment. Prioritizing quality assurance and compliance with regulatory requirements is paramount in delivering safe and reliable products that meet the needs of patients and healthcare providers alike.

Tube/catheter assembly line