Introduction:

Packaging security is a cornerstone of product integrity and consumer trust in today’s fast-paced consumer market. Among the arsenal of packaging solutions, foil seal liners for PET bottle caps emerge as a reliable safeguard, ensuring freshness and deterring tampering. This comprehensive blog post aims to uncover the pivotal role of foil seal liners for PET bottle caps, shedding light on their benefits across various industries and their contribution to elevating packaging security.

The Importance of Packaging Security:

Packaging security is paramount in industries ranging from food to pharmaceuticals and cosmetics. It preserves product freshness and safeguards against contamination and tampering, ensuring consumer safety and trust. Foil seal liners serve as an additional layer of protection for PET bottle caps, enhancing packaging security and peace of mind for consumers.

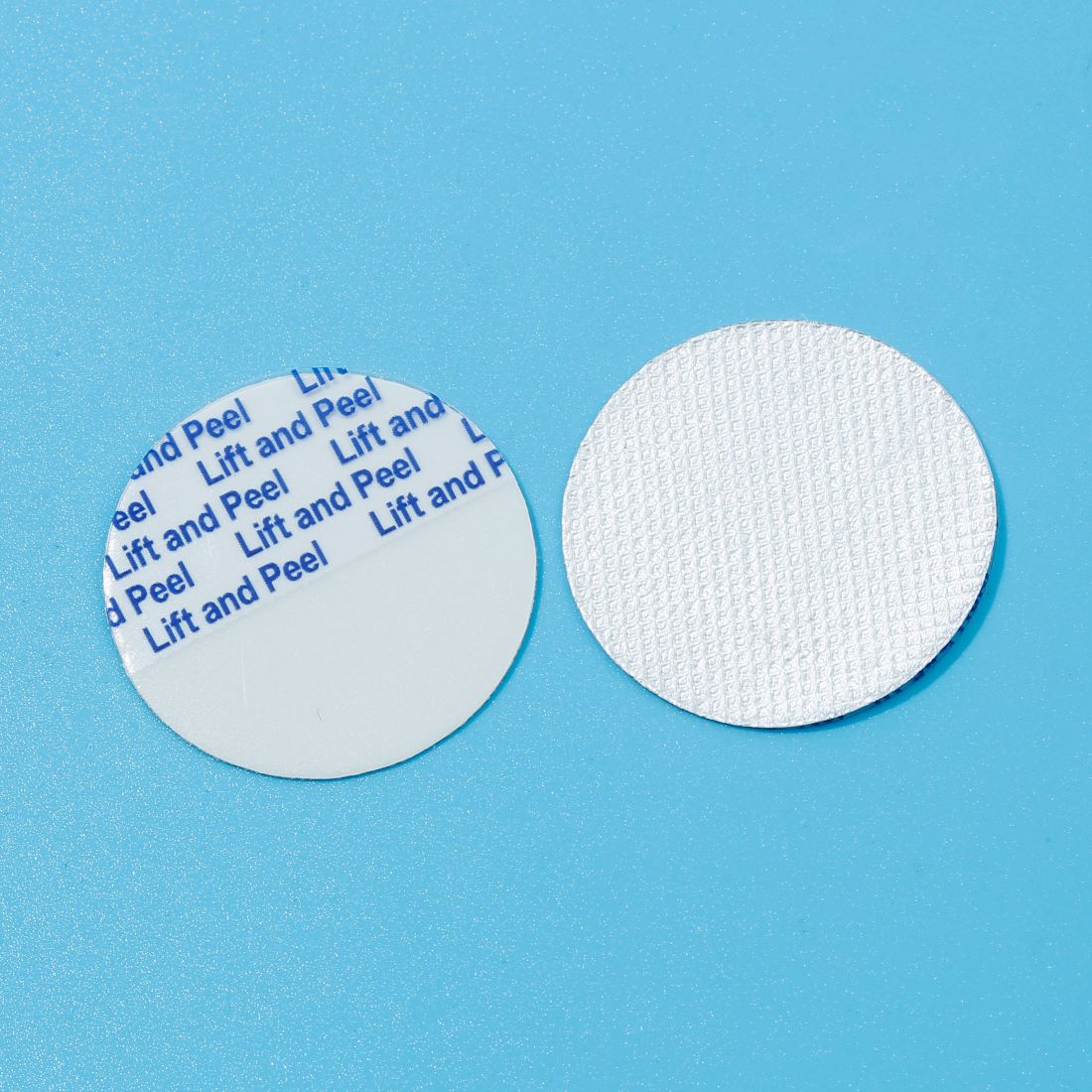

Understanding Foil Seal Liners:

Foil seal liners are specialized closures designed to seal PET bottle caps effectively, preventing air and moisture intrusion. Typically composed of aluminum foil laminated with sealing materials like polymer or wax, these liners create an impenetrable barrier that preserves product freshness and integrity. Using aluminum foil offers superior barrier properties, shielding products from external elements and extending their shelf life.

Benefits of Foil Seal Liners for PET Bottle Caps:

1. Improved Product Freshness:

– Foil seal liners effectively seal PET bottle caps, preventing air and moisture ingress that can compromise product freshness and quality.

– By maintaining an airtight seal, these liners preserve the integrity of the packaged product, ensuring it reaches consumers in optimal condition.

2. Tamper Evidence:

– Foil seal liners provide visual evidence of tampering, deterring malicious activities, and safeguarding against product adulteration.

– Any attempt to tamper with the foil seal results in visible damage, alerting consumers to potential safety concerns and prompting further inspection.

3. Compatibility:

– Foil seal liners are highly versatile and compatible with various PET bottle caps, offering a secure seal that adapts to different packaging configurations.

– Whether used in food, pharmaceutical, or cosmetic packaging, these liners provide reliable protection and peace of mind for manufacturers and consumers alike.

Applications of Foil Seal Liners:

– Food Industry: Foil seal liners are widely used in food packaging to preserve freshness and prevent contamination, particularly for perishable goods like dairy products and condiments.

– Pharmaceutical Industry: In pharmaceutical packaging, foil seal liners ensure product safety and compliance with regulatory standards, maintaining the potency and efficacy of medications.https://sunchoitrading.cn/types-of-materials-used-in-bottle-cap-seal-liners/

– Cosmetic Industry: Foil seal liners add a touch of sophistication to cosmetic packaging while enhancing product protection and preventing leakage or spillage.

How to Choose the Right Foil Seal Liner:

The appropriate foil seal liner for PET bottle caps involves considering factors such as bottle material, size, and sealing requirements. Manufacturers should also assess the desired level of tamper evidence and customization options to effectively meet specific packaging needs.

Industry Trends and Innovations:

– Eco-friendly Options: The rise of sustainable foil seal liner materials and biodegradable alternatives to address environmental concerns and promote eco-friendly packaging solutions.

– Innovative Technologies: Incorporation of advanced technologies like latent semantic indexing and natural language processing in foil seal liner production for enhanced security and customization capabilities.

Conclusion:

Foil seal liners for PET bottle caps emerge as indispensable assets in enhancing packaging security and product protection across various industries. Their ability to preserve freshness, deter tampering, and offer compatibility make them a preferred choice for manufacturers seeking reliable packaging solutions. As industries continue to evolve, foil seal liners are poised to remain at the forefront of innovation, ensuring packaged products’ continued safety and integrity worldwide.

Aluminum foil