The production workflow of a dialysis catheter involves a series of meticulous steps to ensure the highest quality medical device is manufactured. From catheter material selection to catheter design and production, every aspect plays a crucial role in producing a reliable product for patients in need. The process includes catheter moulding, assembly, sterilization, quality control, and packaging, all in compliance with regulatory standards and safety measures. Production efficiency, testing, inspection, and training are also key components in optimizing the workflow. With a focus on quality assurance, scalability, and cost effectiveness, the dialysis catheter production workflow is a complex yet essential process in the medical device industry.

Understanding Dialysis Catheter Manufacturing: An Introduction

- Dialysis catheter manufacturing involves a complex and precise process that requires meticulous attention to detail.

- The production line for dialysis catheters entails various stages, including catheter material selection, sterilization process, catheter moulding, regulatory compliance, and catheter testing.

- Medical device assembly plays a critical role in ensuring the quality and safety of dialysis catheters, with production safety measures and cleanroom manufacturing being essential components.

- Catheter design, catheter tubing production, and dialysis catheter packaging are all integral parts of the manufacturing process.

- Quality assurance and catheter inspection are crucial steps in maintaining high standards of production, while catheter production planning and optimization are key for efficiency.

- Dialysis catheter prototypes are created to test and refine the design before mass production, ensuring dialysis catheter specifications are met.

- Production scalability is also important to meet the growing demand for dialysis catheters while keeping production costs in check.

- Training in catheter manufacturing standards and production workflows is essential for ensuring consistency and reliability in the manufacturing process.

For more information on dialysis catheter manufacturing, visit the Dialysis Catheter Manufacturing Wikipedia page.

Catheter Design: The Foundation of Dialysis Catheter Production

The foundation of dialysis catheter production lies in the meticulous design process. Each catheter is the result of careful consideration of various factors such as catheter material selection, sterilization process, catheter moulding, and regulatory compliance. The design phase sets the tone for the entire catheter manufacturing process, ensuring that the final product meets all quality standards and specifications. Production efficiency, safety measures, and quality assurance are all taken into account during the design phase to optimize the workflow and ensure the production of high quality catheters. Additionally, production planning, cost analysis, and scalability are all considerations that are addressed during the design phase to streamline the production process and ensure timely delivery of dialysis catheters to patients in need.

Material Selection: The Role of Medical Grade Material in Catheter Production

When it comes to the production of dialysis catheters, material selection plays a crucial role. The use of medical grade materials is essential in ensuring the safety and efficacy of these life saving medical devices. Medical grade materials are specifically designed and tested to meet the stringent requirements of the healthcare industry. These materials are biocompatible, non toxic, and resistant to corrosion, making them ideal for use in catheter production.

The selection of medical grade materials for catheter manufacturing is guided by strict standards and regulations to ensure the highest level of quality and patient safety. Manufacturers must consider factors such as the biocompatibility, mechanical properties, and sterilization compatibility of the materials. Additionally, the materials must be able to withstand the rigorous catheter production process, which includes molding, assembly, and packaging.

Using medical grade materials in catheter production not only ensures the reliability of the final product but also contributes to the overall success of the manufacturing process. These materials undergo thorough testing to verify their quality and performance, allowing manufacturers to meet regulatory compliance and production safety measures. By choosing the right materials, manufacturers can optimize their production workflow, improve production efficiency, and enhance the quality of their catheters.

In conclusion, the role of medical grade materials in catheter production is paramount. From material selection to catheter design, production, and testing, using medical grade materials is essential to meet the high standards of the healthcare industry. By prioritizing quality assurance and production safety measures, manufacturers can produce dialysis catheters that meet the specific needs and requirements of patients.

Audience, take a step further in understanding the importance of using medical grade materials in catheter production to ensure the highest level of quality and safety in healthcare.

Catheter Tubing Production: Ensuring Quality and Efficiency

Catheter tubing production plays a crucial role in ensuring the quality and efficiency of dialysis catheter manufacturing. Various factors such as catheter material selection, sterilization process, catheter design, and regulatory compliance contribute to the overall quality of the product.

Production safety measures should be prioritized throughout the catheter production line, from catheter moulding to catheter assembly, to prevent any potential risks or hazards. Cleanroom manufacturing is often utilized to maintain a sterile environment and minimize contamination during production.

Quality assurance and catheter inspection are essential steps to guarantee that the manufactured catheters meet the required medical grade standards. Production testing and validation are conducted to ensure that the products adhere to dialysis catheter specifications.

Efficiency in catheter tubing production can be achieved through optimized production workflows, production planning, and using manufacturing equipment capable of high production scalability. Additionally, providing proper catheter production training to the staff can enhance the efficiency of the production process.

In conclusion, by focusing on quality control measures, adherence to manufacturing standards, and optimizing production workflows, catheter tubing production can ensure the production of high quality and efficient dialysis catheters.

Call to action: For more information on dialysis catheter production workflow, visit the Wikipedia page on Dialysis Catheter Manufacturing.

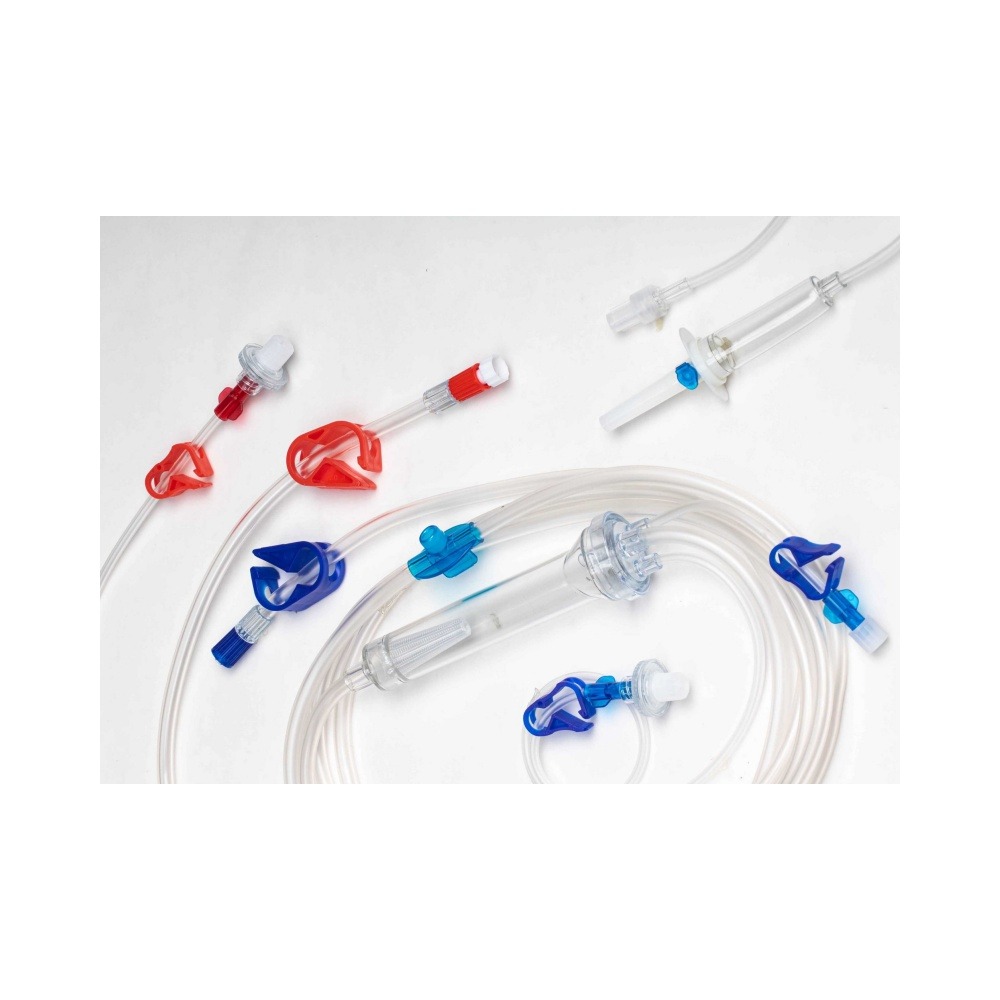

Dialysis Blood Tube Assembly Line