we offer state-of-the-art production machines for medical consumables like IV sets, syringes, related components, and blood collection tubes, as well as for IV pharmaceuticals such as IV fluids in PP bottles, bags, and vials. With our cutting-edge machines, we’re redefining medical consumable production and pharmaceutical manufacturing.

Medical Consumable Production Machines:

Our production machines for medical consumables are crafted for perfection, enabling efficient manufacturing of IV sets, syringes, and related components, as well as blood collection tubes. These machines maintain the highest standards of quality and precision, ensuring each product meets regulatory requirements and contributes to superior patient care.

IV Pharmaceutical Production Machines:

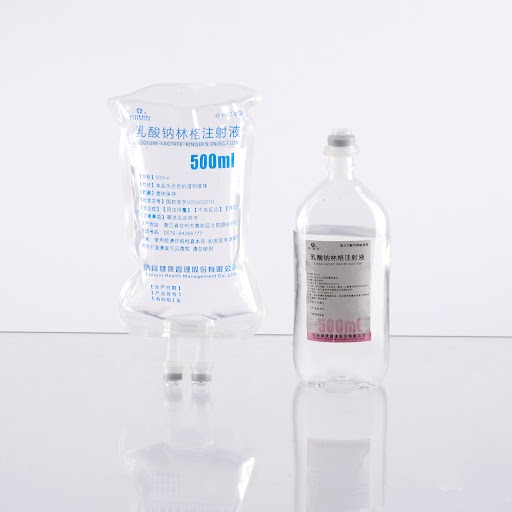

When it comes to IV pharmaceuticals, our production machines lead the way in innovation. They efficiently fill IV fluids into PP bottles and bags and handle vial production with advanced technology to optimize efficiency and maintain product integrity. Automated processes and rigorous quality control measures guarantee that our machines deliver pharmaceutical solutions that meet the highest standards of safety and efficacy.