IV Bottle Inspection Machine: Enhancing Pharmaceutical Production with Advanced Features and Benefits

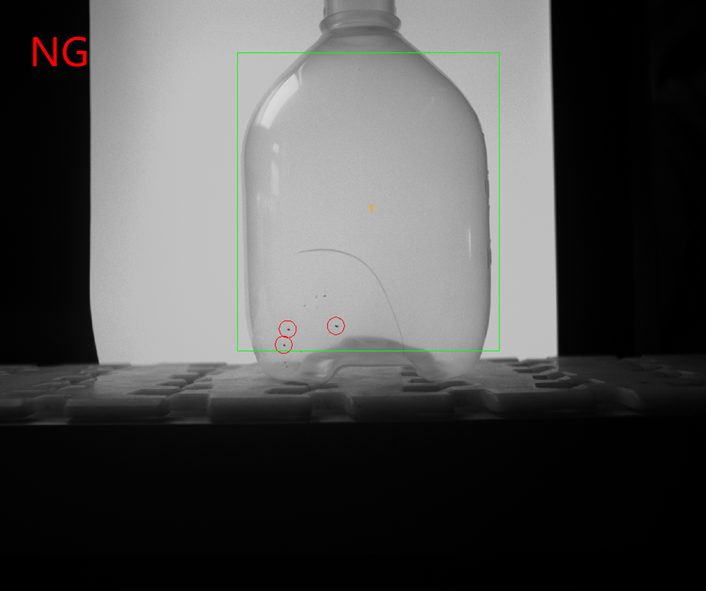

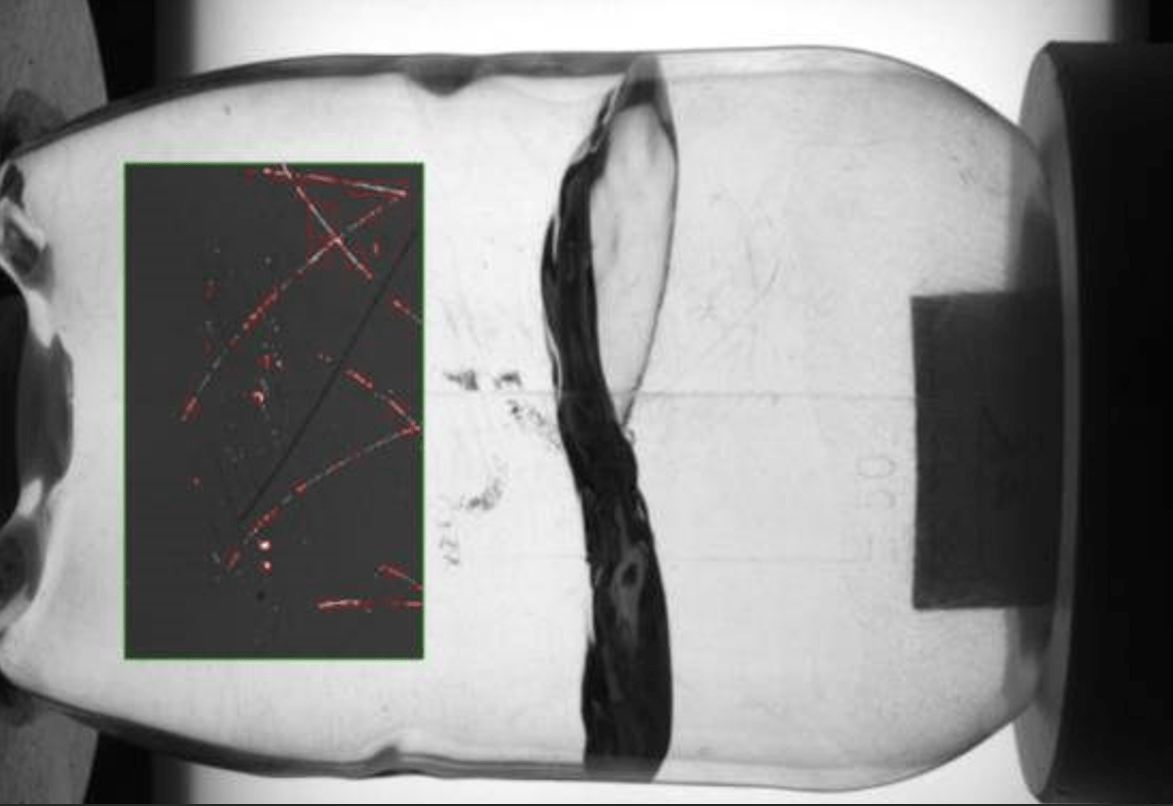

An IV bottle inspection machine plays a crucial role in enhancing pharmaceutical production by providing advanced features and benefits. The automated inspection capabilities ensure quality assurance throughout the manufacturing process. The machine’s accuracy in defect detection and high speed inspection contribute to improved efficiency in production. It also aids in contamination prevention and sterile processing, […]