Understanding IV Solution Packaging Material Specifications

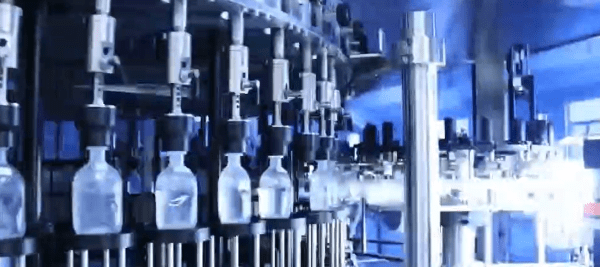

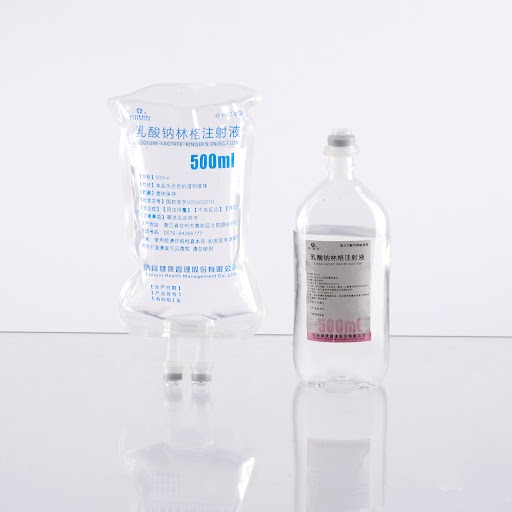

intravenous (IV) solutions play a critical role in patient care, enabling the administration of fluids, nutrients, and medications directly into the bloodstream. The bottles or bags that contain these solutions are just as crucial, as they must ensure the safety, efficacy, and sterility of their contents. This comprehensive post delves into the specifications for IV […]