Cap Assembly Machine

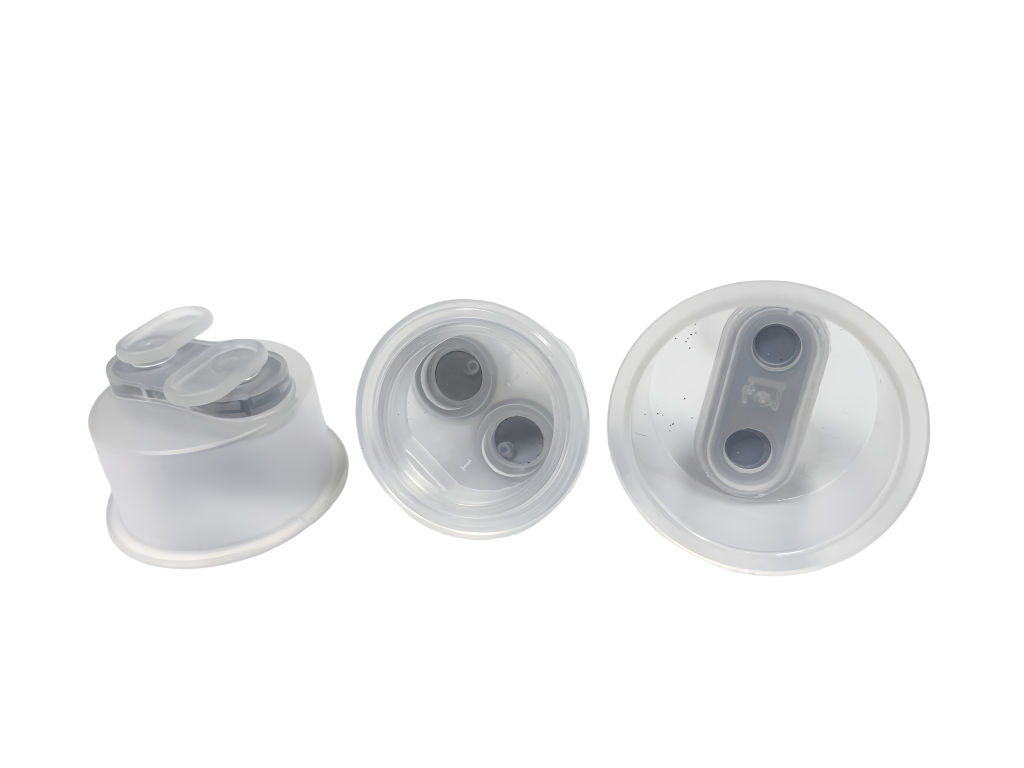

Infusion cap (PP,PE) assembly machine

The machine is used for assembly the infusion cap , inner cap ,outter cap , and rubber stopper assembly .

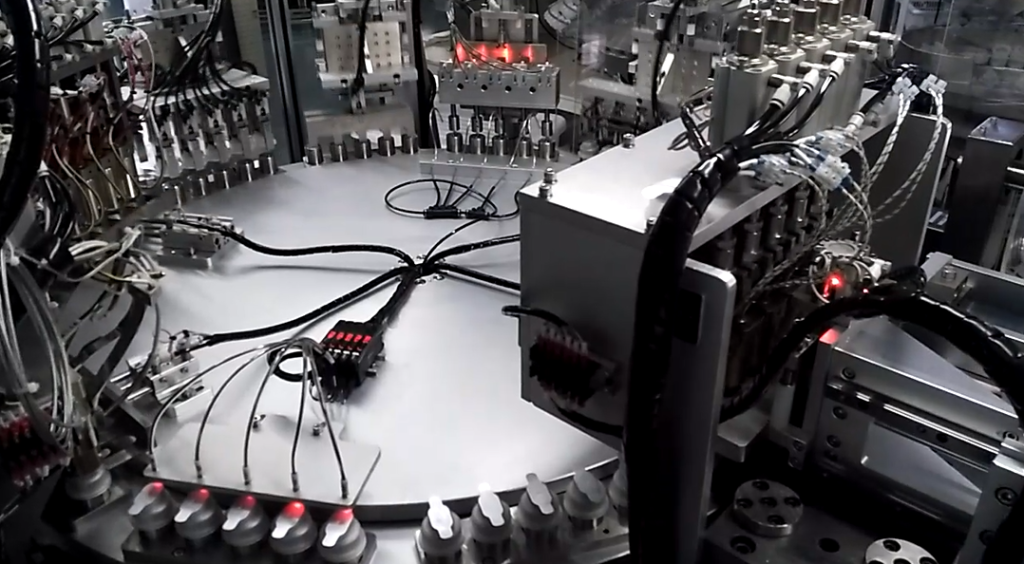

Machine parameter

| ITEM | Unit | Qty | |

| Output | 16-24 heads infusion cap assembly machine | caps/min | 200caps- 250caps |

| Power consumption(380V) | Main motor | kW | 0.75 |

| Vibration motor | kW | 0.5×3 | |

| Air consumption | 0.6-0.8 Mpa | m3/min | 0.6 |

| Vaccum | Mpa | 0.004 | |

| volume flow rate | m3/min | 1.5 | |

| noise | db | <85 | |

| Dimension | L×W×H | mm | 2700*2100*1150 |

| Weight | kg | 1500 | |

Main configuration

a. body and frame

1). Exposed part 304 polished (brushed) or engineering plastic

2).Frame and chain drive part 45# or engineering plastic

b. Pneumatic components

3).Solenoid valve American MAC

4). Cylinder camozzi, Italy

c. Electrical control

5).Control switch Schneider

6).AC contactor Schneider

7).Motor relay Schneider

8). Frequency converter Mitsubishi Japan

9).PLC program controller SIEMENS, Germany

10).Proximity switch/travel switch Autonics

11).Touch screen Japanese pro-face

12). High voltage transformer Chinese Fenghua

d. Others

13).reducer Chinese brand

Infusion foil cap machine

Performance Specification

Full automatically

| No | Spec |

| 1 | Output:5500-6000 caps/h (final speed depend on the product ) |

| 2 | PLC control |

| 3 | Power source:voltage:380V,3 phases 5 lines compressor air:0.7MPA.1.0M3/MIN hose access month size >16MM |

| 4 | Installation size:3100L×3075W×1800H(mm),to actual prevail. |

| 5 | Running rate 95% above , Assembly pass rate: above 98% (Automatic elimination of defective products) |

| 6 | Design, materials , processing parts ,other spare parts and control method is according to the pharma packing materials production machinery GMP standard . |

| 7 | The installation height of clear room >1500mm |

| 8 | The size of the door/corridor that the equipment moves in must be greater than 1500MM. The equipment on the second floor should be moved to the platform |