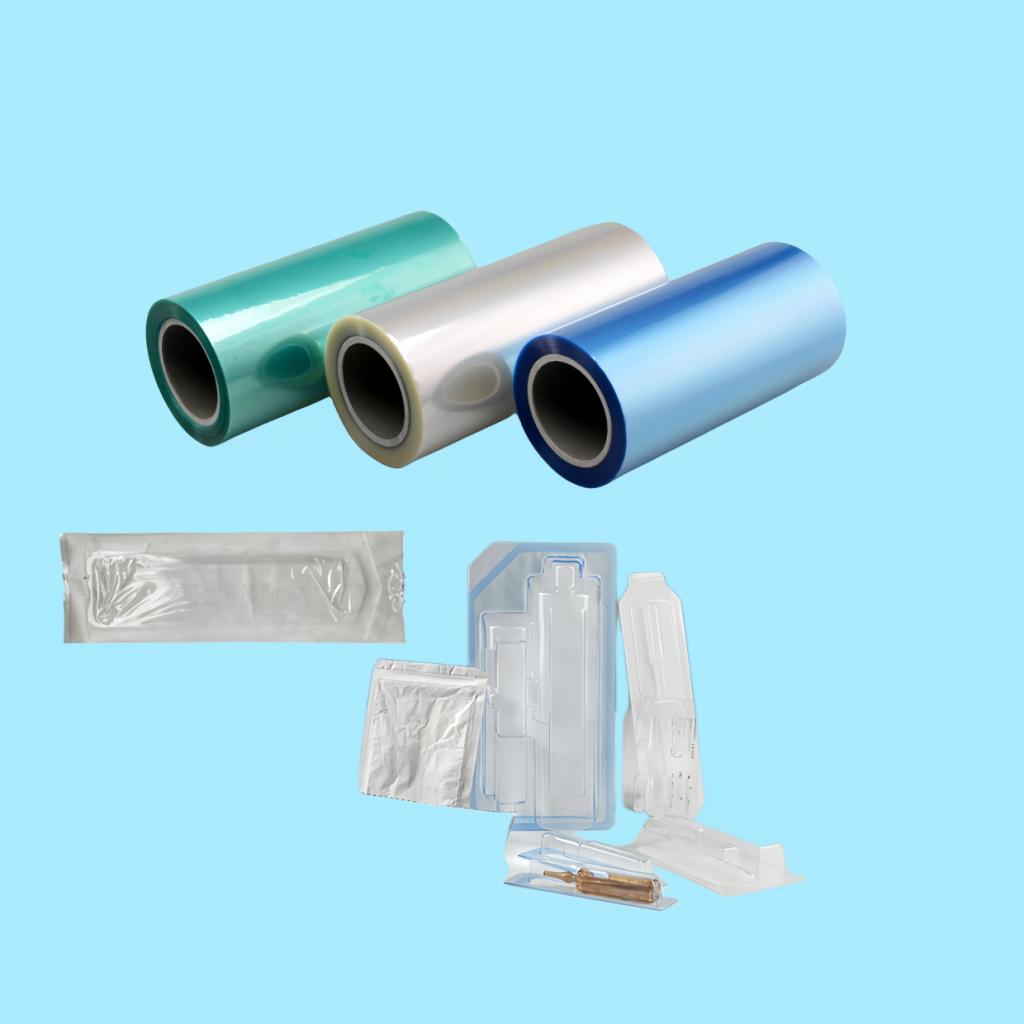

Blister Packaging Material

For blister packaging : we can provide medical coated paper,medical crepal paper , medical PVC film roll , PP/PE,PA/PE film and customize for you .

- PVC Film: Suitable for both soft and hard blister packaging, offers clarity and formability, compatible with various sterilization methods.

- PVDC Film: Used in both soft and hard blister packaging, provides excellent barrier properties against moisture and oxygen, compatible with multiple sterilization methods.

- PE/PP Film: Versatile for soft and hard blister packaging, offers flexibility and durability, compatible with various sterilization methods.

- PA/PE Film: Used in both soft and hard blister packaging, provides excellent barrier properties and puncture resistance, compatible with sterilization processes.

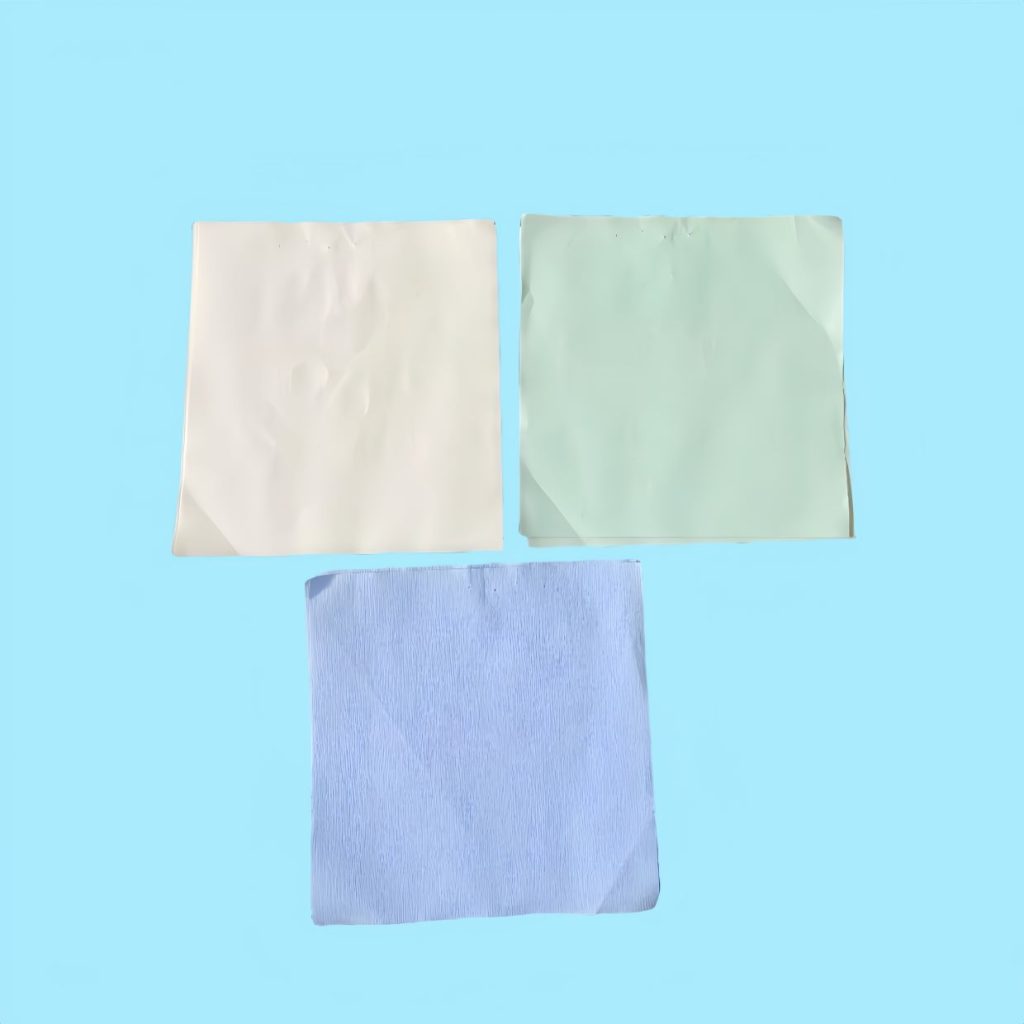

Mecial crepe paper fo medical device packaging

- Sterilization Compatibility: Works with various sterilization methods.

- Tear Resistance: Durable during handling and sterilization.

- Absorbency: Prevents moisture buildup.

- Conformability: Shapes to medical devices for proper coverage.

- Disposable: Single-use for hygiene and safety.

- Biocompatibility: Safe for medical use.

- Regulatory Compliance: Meets industry standards.

Medical coated paper

- Enhanced Barrier: Provides a protective barrier against moisture, grease, and contaminants, safeguarding the contents of the packaging.

- Sterilization Compatibility: Compatible with steam, ethylene oxide (EtO), and gamma radiation sterilization methods, ensuring the maintenance of sterility for medical products.

- Printability: Offers excellent printability for clear and legible labeling of medical packaging, including instructions, product information, and branding.

- Durability: The coating enhances the paper’s strength and durability, making it resilient during handling, transportation, and storage.

- Compliance: Manufactured to meet regulatory standards for medical device packaging, ensuring adherence to quality, safety, and performance requirements