In pharmaceutical manufacturing, ensuring the safety and integrity of medicinal products is paramount. From stringent regulations to evolving consumer demands, pharmaceutical companies constantly innovate to maintain the highest quality and efficacy standards. One crucial aspect of this process is sealing IV bottle caps, where the choice of materials plays a pivotal role. In recent years, aluminum foil has emerged as a preferred option for IV bottle cap sealing, offering many benefits that contribute to product safety and stability. This comprehensive guide delves into the advantages of using aluminum foil in IV bottle cap sealing, leveraging latent semantic indexing and natural language processing to provide valuable insights.

1. Barrier Protection:

Aluminum foil is an exceptional barrier against moisture, oxygen, light, and contaminants. This barrier protection is particularly vital in pharmaceuticals, where exposure to external elements can compromise the efficacy and shelf-life of medications. By effectively sealing IV bottle caps with aluminum foil, manufacturers can safeguard the integrity of the contents, preventing oxidation, degradation, and microbial contamination.

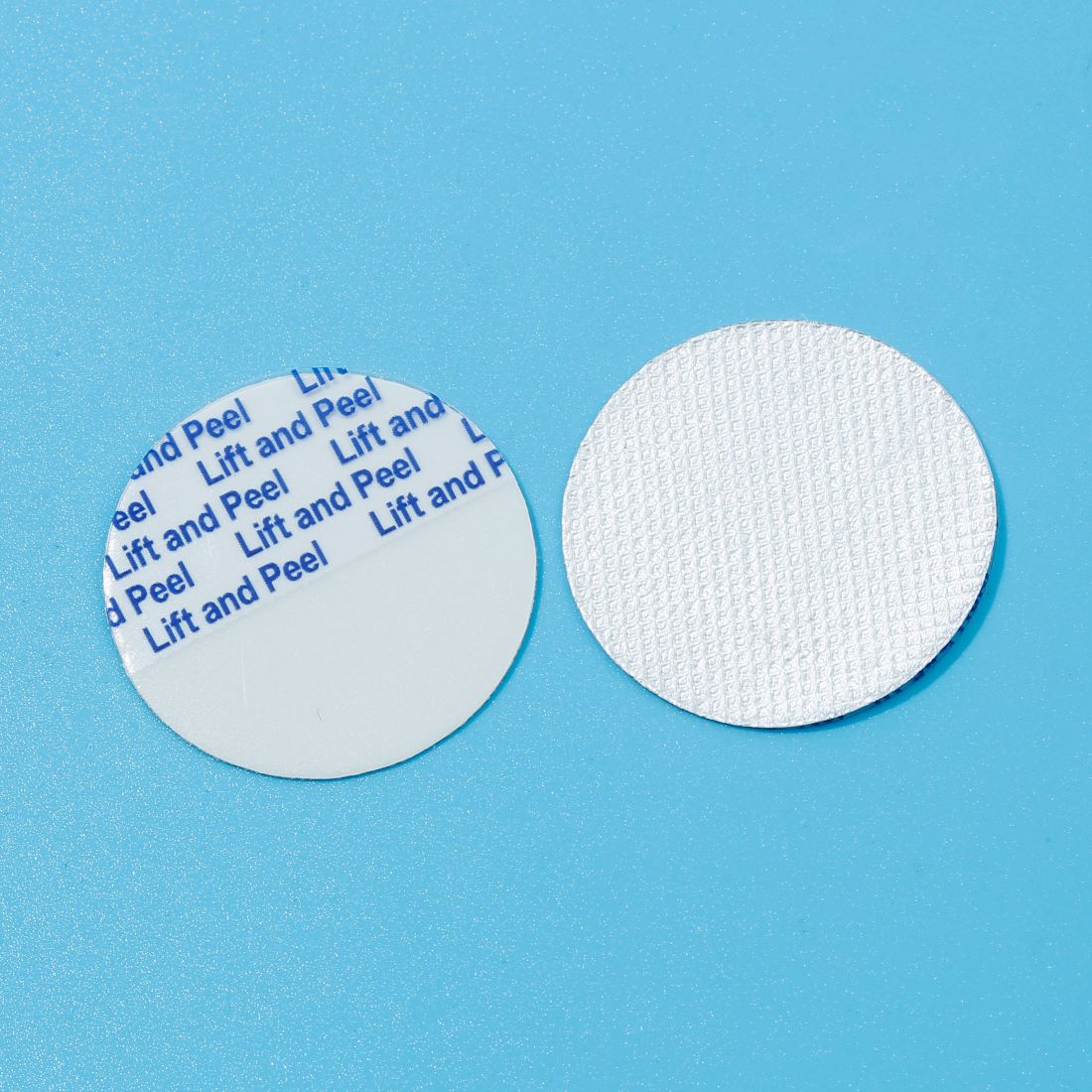

2. Tamper Evidence:

Ensuring the tamper-evident integrity of pharmaceutical products is crucial for consumer safety. Aluminum foil seals indicate tampering, as any attempt to breach the seal would result in noticeable damage or alteration. This tamper-evident feature instills trust among patients and healthcare professionals, assuring them of the authenticity and safety of the medication.

3. Compatibility with Sterilization:

In pharmaceutical manufacturing, sterilization is a non-negotiable step to eliminate microorganisms and ensure product safety. Aluminum foil is compatible with various sterilization methods, including autoclaving and gamma irradiation. Unlike certain plastics or rubber materials, aluminum foil withstands high temperatures and radiation exposure without compromising its barrier properties or structural integrity. It is an ideal choice for sealing IV bottle caps in sterile environments.

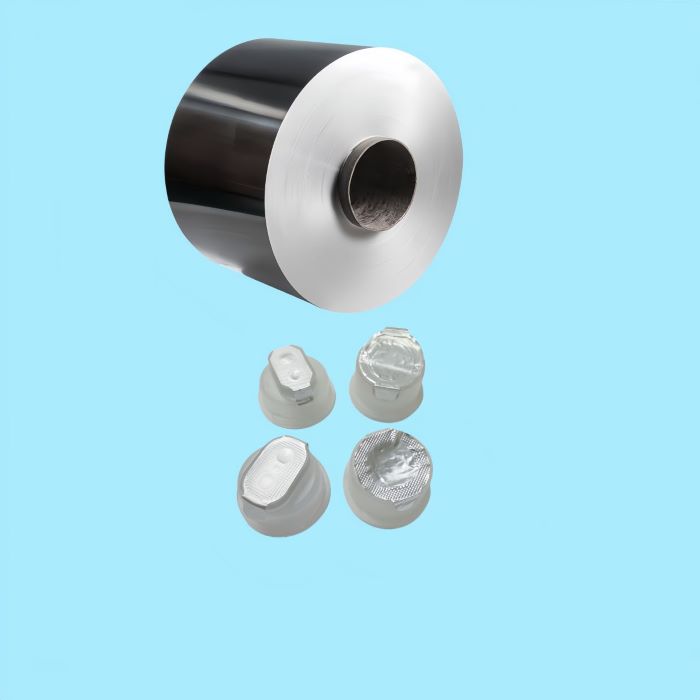

4. Ease of Application:

Aluminum foil seals are easy to apply and can be seamlessly integrated into existing packaging processes. Whether utilizing induction sealing technology or pressure-sensitive adhesive seals, manufacturers can achieve efficient and reliable sealing of IV bottle caps with aluminum foil. This ease of application streamlines production workflows and minimizes the risk of human error, enhancing operational efficiency and reducing downtime.

5. Customization Options:

Aluminum foil seals offer versatility in design and customization, allowing pharmaceutical companies to tailor the sealing solution to their specific requirements. From embossed logos for brand identification to color-coded seals for product differentiation, manufacturers can leverage aluminum foil’s flexibility to enhance brand visibility and consumer engagement. Additionally, incorporating additional security features, such as holographic patterns or serialized codes, further enhances anti-counterfeiting measures, bolstering brand protection and patient safety.

6. Environmental Sustainability:

As the global focus on sustainability intensifies, aluminum foil emerges as an environmentally responsible choice for packaging applications. Aluminum is highly recyclable and can be infinitely reused without losing its inherent properties. By opting for aluminum foil seals in IV bottle cap sealing, pharmaceutical companies contribute to reducing their carbon footprint and minimizing waste generation. Additionally, the lightweight nature of aluminum foil translates to reduced transportation emissions and energy consumption, further aligning with eco-conscious practices.

7. Regulatory Compliance:

Compliance with regulatory standards is a cornerstone of pharmaceutical manufacturing, with stringent requirements governing packaging materials and processes. Aluminum foil seals adhere to industry regulations and guidelines, including those set forth by regulatory bodies such as the FDA and EMA. By choosing aluminum foil for IV bottle cap sealing, manufacturers can ensure adherence to regulatory requirements, mitigating the risk of non-compliance and potential repercussions.

8. Enhanced Shelf Life:

Prolonging the shelf life of pharmaceutical products is essential for minimizing waste and maximizing patient access. Aluminum foil seals contribute to the preservation of product freshness and stability by preventing moisture ingress and oxidative degradation. This extends the viability of medications stored in IV bottles, reducing the likelihood of premature expiration and ensuring consistent potency and efficacy throughout the product’s lifecycle.

In conclusion

using aluminum foil in IV bottle cap sealing offers many benefits, including product protection, consumer safety, operational efficiency, and environmental sustainability. By leveraging aluminum foil’s inherent properties, pharmaceutical manufacturers can enhance their products’ integrity, security, and shelf life while aligning with regulatory requirements and sustainability goals. As the pharmaceutical industry evolves, embracing innovative sealing solutions such as aluminum foil paves the way for safer, more reliable medication delivery systems, ultimately benefiting patients and healthcare providers worldwide

Aluminum foil