Automated dialysis blood tube assembly machines are revolutionizing the healthcare industry with their advanced technology and precision assembly capabilities. These machines are designed to automate the assembly process of blood tube manufacturing for dialysis machines, streamlining the production of crucial components for the dialysis process.

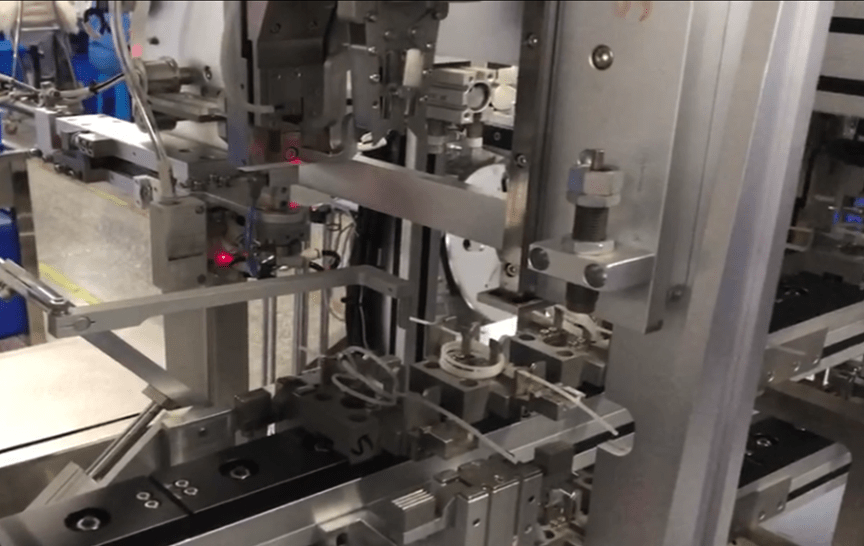

Key features of automated dialysis blood tube assembly machines include high speed assembly, leakage detection, and block detection. By incorporating these features, these machines ensure the seamless production of blood tubes with minimal errors, resulting in enhanced efficiency and quality control in medical device manufacturing.

The integration of automation in healthcare has led to significant advancements in dialysis machine design, allowing for more sophisticated and reliable solutions for patients in need of dialysis treatment. Industrial automation in healthcare, particularly in the context of dialysis technology, has paved the way for improved patient outcomes and increased access to life saving treatments.

With automated dialysis blood tube assembly machines, healthcare facilities can streamline their blood tube processing, reduce the risk of errors, and enhance overall patient care. These machines play a crucial role in the dialysis process automation, ensuring the safe and efficient production of dialysis bloodline components for medical use.

Overall, automated dialysis blood tube assembly machines represent a technological breakthrough in the healthcare industry, offering innovative solutions for the manufacturing of critical components for dialysis machines. By leveraging the power of automation, healthcare providers can enhance the quality and reliability of their dialysis services, ultimately improving the lives of patients worldwide.

Understanding Dialysis Technology and Machine Automation

Automated dialysis technology has revolutionized the process of blood tube assembly in healthcare settings. The integration of machine automation in the dialysis process has greatly improved efficiency and precision in the production of blood tube components. By utilizing automated assembly machines, manufacturers are able to streamline the blood tube manufacturing process and ensure consistent quality in the final product.

Dialysis machine automation plays a crucial role in the assembly line automation of dialysis bloodline components. These advanced solutions involve high speed assembly of blood tubes, with features such as leakage detection and block detection for enhanced safety measures. The design of medical assembly machines for dialysis is focused on precision assembly to meet the strict standards of medical device manufacturing.

Industrial automation in healthcare, particularly in the field of dialysis machine innovation, has propelled the industry towards more efficient and reliable blood tube processing. With the introduction of automated dialysis technology, the production of blood tubes has become more streamlined, allowing for faster turnaround times and improved quality control measures.

In conclusion, the integration of machine automation in dialysis technology has significantly improved the efficiency and precision of blood tube assembly processes. With advancements in high speed assembly and advanced solutions such as leakage detection, the healthcare industry is able to ensure the consistent production of high quality blood tubes for dialysis procedures.

The Role of Automated Assembly in Blood Tube Manufacturing

Automated assembly plays a crucial role in blood tube manufacturing, revolutionizing the dialysis process for the better. With the advent of automated dialysis blood tube assembly machines, the efficiency and precision of the assembly line have been significantly enhanced. These machines utilize advanced technologies to streamline the production of blood tube components, ensuring high speed assembly with minimal errors.

Key components of automated assembly in blood tube manufacturing include leakage detection and block detection systems. These features help to identify and rectify any issues in real time, ensuring the production of high quality blood tubes. The integration of automation in the assembly process has led to improved overall product quality and reduced costs, making it a game changer in the medical device manufacturing industry.

Automation in blood tube manufacturing also allows for the customization of dialysis bloodline components, catering to specific patient needs. This level of precision assembly ensures that each blood tube is tailored to the individual, providing advanced dialysis solutions for improved patient outcomes. Furthermore, industrial automation in healthcare has paved the way for innovation in dialysis machine design, pushing the boundaries of what is possible in the field of healthcare technology.

Overall, the role of automated assembly in blood tube manufacturing cannot be overstated. It has revolutionized the dialysis process, leading to increased efficiency, improved product quality, and enhanced patient care. Embracing automation in healthcare is not just a trend but a necessity for the future of medical manufacturing. Through continuous advancements in automated assembly technology, the healthcare industry is poised to make significant strides in improving patient outcomes and revolutionizing medical device production.

For more information on automated assembly in healthcare, visit the Wikipedia page on ‘Automation in healthcare’.

Exploring the Dialysis Process Automation and Medical Assembly Machine

The automated dialysis blood tube assembly machine is a cutting edge technology that revolutionizes the dialysis process. This medical assembly machine utilizes advanced automation to streamline the production of blood tubes for dialysis machines. By integrating precision assembly and high speed processing, this innovative system enhances efficiency and accuracy in blood tube manufacturing.

The dialysis process automation involves the use of automated assembly to produce dialysis bloodline components. This machine is designed to handle the tube assembly process with utmost precision, ensuring seamless integration of various components. With industrial automation in healthcare, the assembly line automation in these machines results in improved production rates and quality control.

One of the key features of the automated dialysis blood tube assembly machine is its ability to detect leakages and blockages in the blood tubes. This leakage detection system ensures that the blood tubes are properly sealed to prevent any potential risks during dialysis treatment. Additionally, the block detection mechanism helps identify any obstacles in the tube assembly process, minimizing errors and ensuring smooth operation.

With the integration of advanced dialysis solutions, this medical assembly machine offers unparalleled efficiency and reliability in blood tube processing. The high speed assembly capabilities of this machine enable swift production of blood tubes, meeting the demands of healthcare facilities for quick and accurate supply.

In conclusion, the automated dialysis blood tube assembly machine represents a significant advancement in medical device manufacturing. By leveraging automation and innovative technology, this machine enhances the dialysis process, ensuring optimal performance and patient safety in healthcare settings. For more information on automated dialysis and medical assembly machines, visit the Wikipedia page on industrial automation.

The Impact of Healthcare Automation and Dialysis Machine Design

Healthcare automation and dialysis machine design have revolutionized the medical industry, enhancing efficiency and precision in the dialysis process. Automated dialysis machines have significantly improved patient care and outcomes by streamlining the blood tube assembly process.

- Automated dialysis technology has introduced advanced solutions for high speed assembly of blood tube components, such as dialysis bloodline components. This automation ensures precision assembly, reducing the risk of errors and enhancing the quality of blood tube production.

- The integration of machine automation in healthcare has led to the development of innovative dialysis machine designs that focus on optimizing the tube assembly process. These machines are equipped with features like leakage detection and block detection, further enhancing patient safety and reducing the likelihood of complications during dialysis.

- Industrial automation in healthcare has transformed the way blood tube manufacturing is carried out, with automated assembly lines streamlining the production process. This not only increases efficiency but also allows for faster turnaround times and improved overall productivity in medical device manufacturing.

In conclusion, the impact of healthcare automation and dialysis machine design cannot be overstated. These advancements have revolutionized the dialysis process, providing patients with access to advanced, efficient, and safe treatment options. Incorporating automation in healthcare has paved the way for improved patient outcomes and enhanced overall quality of care. Explore Wikipedia to learn more about the fascinating world of automated dialysis technology and machine design.

Insight into Tube Assembly Process and Precision Assembly

The tube assembly process in automated dialysis blood tube assembly machines involves precision assembly to ensure the production of high quality blood tube components for dialysis machines. Through machine automation, dialysis technology has advanced to streamline the assembly line process, leading to efficient blood tube manufacturing.

Key components of the tube assembly process include automated assembly of dialysis bloodline components, ensuring accurate placement and connection of tubes for seamless operation. With the aid of medical assembly machines, healthcare automation has significantly improved the overall dialysis process automation.

Precision assembly plays a crucial role in the production of blood tubes, where advanced dialysis solutions rely on high speed assembly to meet the demands of the healthcare industry. This process involves the detection of leakages and blocks in the tubes, ensuring the safety and effectiveness of the dialysis machine design.

The industrial automation in healthcare has revolutionized the way blood tube processing is carried out, with a focus on enhancing the quality and reliability of medical device manufacturing. By incorporating assembly line automation, the efficiency of the tube assembly process has been greatly enhanced, leading to innovative dialysis machine designs.

In conclusion, the tube assembly process and precision assembly in automated dialysis blood tube assembly machines are essential for meeting the growing demands of the healthcare industry. With a focus on accuracy, efficiency, and safety, these machines play a critical role in delivering high quality blood tube components for dialysis machines.

The Future of Blood Tube Production and Medical Device Manufacturing

Automated dialysis technology has revolutionized the medical device manufacturing industry with the introduction of high speed assembly machines. These automated assembly machines have significantly improved the efficiency and precision of blood tube production for dialysis patients.

The future of blood tube manufacturing lies in the seamless integration of automated assembly processes. By utilizing advanced dialysis solutions, medical device manufacturers are able to streamline the production of dialysis bloodline components. These automated machines not only enhance the production speed but also ensure the quality and accuracy of each blood tube manufactured.

One key feature of these medical assembly machines is their ability to detect leakages and blocks in the assembly line. This ensures that each blood tube produced meets the required standards for patient safety. The incorporation of industrial automation in healthcare has led to a significant improvement in the overall dialysis process automation.

With the continuous innovation in dialysis machine design, the future of blood tube production is moving towards complete automation. This not only benefits the healthcare industry by increasing efficiency but also ensures the consistent quality of blood tube manufacturing. The precision assembly of blood tubes plays a critical role in the dialysis process, making automation an essential component in medical device manufacturing.

Overall, the future of blood tube production and medical device manufacturing is focused on utilizing automated assembly machines to streamline the manufacturing process and improve the quality of dialysis bloodline components. This shift towards automation in healthcare is paving the way for a more efficient and reliable production of blood tubes for dialysis patients.

For more information on automated dialysis technology, medical device manufacturing, and the future of blood tube production, visit the Wikipedia page on automated assembly machines.

Dialysis Blood Tube Assembly Line