Introduction:

In the intricate world of pharmaceutical manufacturing, every component plays a crucial role in ensuring the safety and integrity of the final product. Among these components, bottle cap seal liners stand out as unsung heroes, silently safeguarding the contents of medication bottles from external contaminants and preserving their efficacy. This comprehensive guide delves into the various types of materials used in bottle cap seal liners, shedding light on their significance and functionalities in pharmaceutical packaging.

Understanding Bottle Cap Seal Liners:

Before delving into the types of materials utilized in bottle cap seal liners, it’s essential to grasp their fundamental purpose. These liners serve as a barrier between the contents of the bottle and the external environment, preventing moisture, gases, and other contaminants from compromising the quality of the pharmaceutical product. Additionally, they provide tamper-evident features, assuring consumers of product safety and authenticity.

Types of Materials:

1. Polyethylene (PE) Foam Liners:

– Polyethylene foam liners are widely used in pharmaceutical packaging due to their excellent sealing properties and chemical resistance.

– These liners create a reliable seal, effectively preventing leakage and contamination.

– PE foam liners are available in various thicknesses, catering to different packaging requirements.

2. Polypropylene (PP) Foam Liners:

– PP foam liners are another popular choice in bottle cap seal liners, valued for their versatility and durability.

– These liners exhibit high chemical resistance, making them suitable for various pharmaceutical products.

– PP foam liners offer enhanced tamper-evident features, ensuring product integrity during transportation and storage.

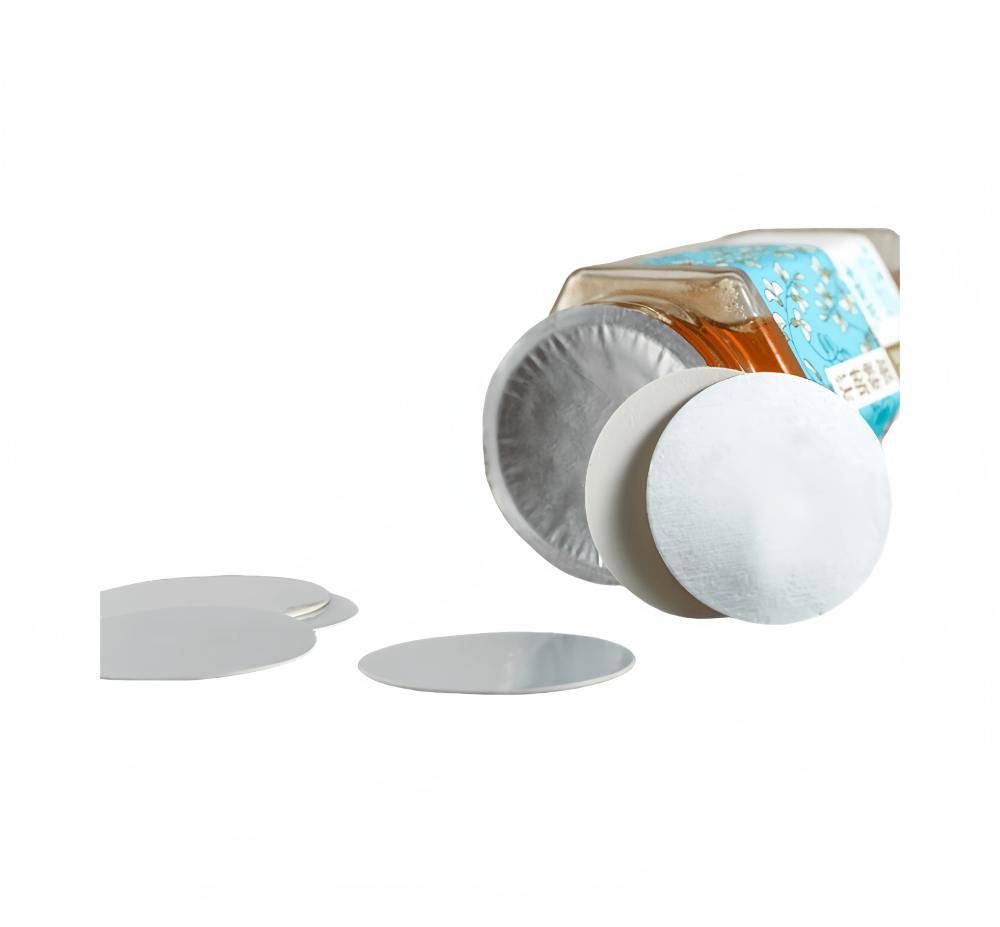

3. Induction Seal Liners:

– Induction seal liners employ a different mechanism for sealing bottles, utilizing an aluminum foil layer laminated with a polymer film.

– During the induction sealing process, electromagnetic induction heats the foil, melting the polymer and creating an airtight seal upon cooling.

– These liners provide superior barrier properties, effectively preserving the freshness and potency of pharmaceuticals.

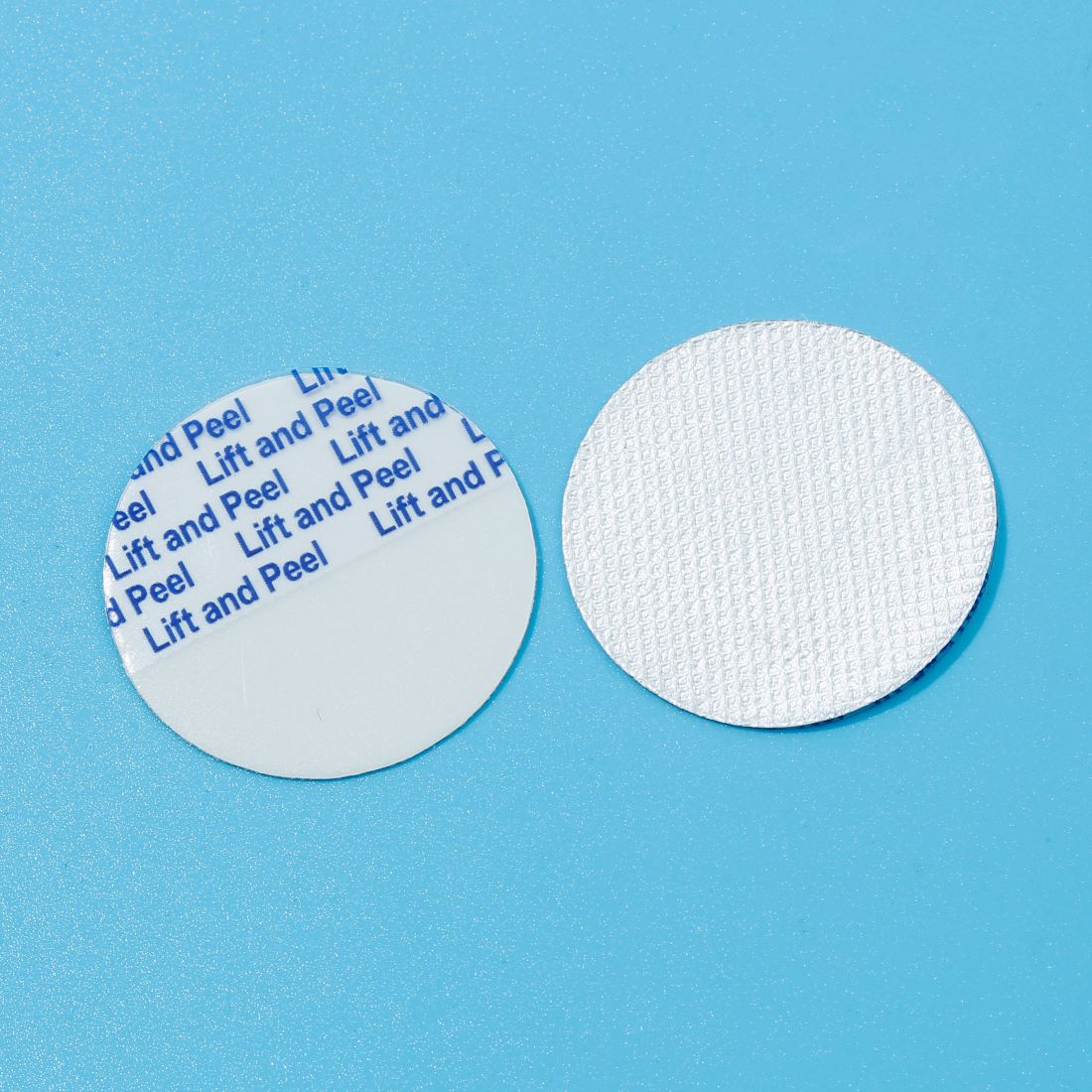

4. Pressure Sensitive Liners:

– Pressure-sensitive liners feature a layer of adhesive that adheres to the bottle rim upon application of pressure.

– These liners offer ease of application and tamper evidence, as any attempt to open the bottle results in visibly disturbing the liner.

– Pressure-sensitive liners are compatible with various bottle materials, including glass and plastic.

5. Expanded Polyethylene (EPE) Liners:

– EPE liners are known for their cushioning properties, protecting against shock and vibration during transportation.

– These liners are particularly beneficial for fragile pharmaceutical products that require extra care during handling and shipping.

– EPE liners complement other seal materials, enhancing the overall security and integrity of the packaging.

Significance of Material Selection:

The choice of material for bottle cap seal liners significantly impacts the performance and efficacy of pharmaceutical packaging. Factors such as compatibility with the product, resistance to moisture and chemicals, and adherence to regulatory standards must be carefully considered during material selection. By utilizing advanced natural language processing (NLP) algorithms and latent semantic indexing (LSI), manufacturers can optimize material selection based on specific requirements, thereby enhancing pharmaceutical products’ overall quality and safety.

Future Trends and Innovations:

As the pharmaceutical industry continues to evolve, so do the materials and technologies used in bottle cap seal liners. Future trends may witness the emergence of eco-friendly materials, such as biodegradable polymers, to address sustainability concerns. Furthermore, advancements in nanotechnology and intelligent packaging solutions are poised to revolutionize bottle cap seal liners, offering enhanced functionality and real-time monitoring capabilities.

Conclusion:

In pharmaceutical packaging, bottle cap seal liners are vital in ensuring product safety, integrity, and compliance with regulatory standards. By understanding the diverse range of materials available for these liners and leveraging NLP and LSI techniques for optimization, manufacturers can make informed decisions that enhance the quality and efficacy of pharmaceutical products. As innovation continues to drive the industry forward, the evolution of bottle cap seal liners promises to uphold the highest standards of protection and preservation for medications worldwide.

Aluminum foil