Introduction: Quality control in pharmaceutical manufacturing has undergone a significant transformation over the years, driven by technological advancements and regulatory demands. This article explores the evolution of QC techniques, from traditional methods to cutting-edge technologies, and their impact on product quality and compliance.

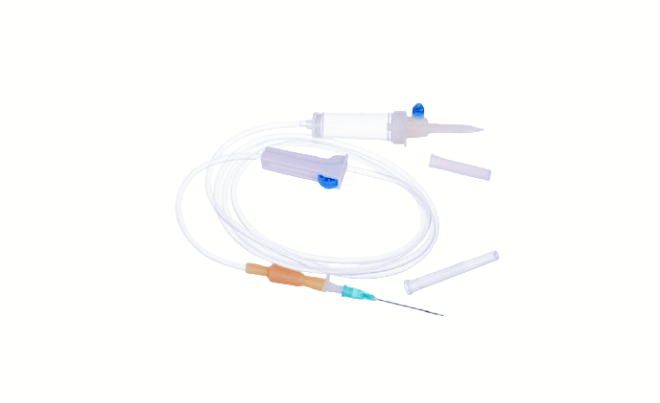

Traditional vs. Modern Approaches to Quality Control in Medical Disposable Manufacturing

The landscape of quality control in medical disposable manufacturing has evolved significantly, with modern technologies revolutionizing traditional approaches. This article compares and contrasts traditional QC methods, such as visual inspection and manual testing, with modern techniques, including automated inspection systems and real-time monitoring. By embracing innovative QC solutions, manufacturers can enhance efficiency, accuracy, and compliance while maintaining the highest standards of product quality.

Navigating Regulatory Compliance in Quality Control for Pharmaceutical Manufacturing

In the highly regulated pharmaceutical industry, adherence to stringent quality standards is non-negotiable. This article explores the complex regulatory landscape governing quality control in pharmaceutical manufacturing, highlighting key guidelines and standards imposed by regulatory bodies such as the FDA and EMA. By implementing robust quality control systems that align with regulatory requirements, manufacturers can ensure product safety, efficacy, and compliance throughout the production process.

The Role of Data Analytics in Enhancing Quality Control Efficiency

Data analytics has emerged as a game-changer in quality control, offering manufacturers unprecedented insights into production processes and product quality. This article examines the role of data analytics in enhancing QC efficiency, from predictive analytics for identifying potential defects to real-time monitoring for proactive decision-making. By harnessing the power of data, manufacturers can optimize QC processes, minimize waste, and drive continuous improvement in product quality.

Achieving Supply Chain Resilience Through Quality Control in Medical Disposable Manufacturing

The COVID-19 pandemic underscored the critical importance of supply chain resilience in the healthcare sector, particularly in the production of essential medical disposables. This article explores how quality control plays a pivotal role in ensuring supply chain resilience, from raw material sourcing to distribution. By implementing rigorous QC measures and fostering collaboration across the supply chain, manufacturers can mitigate risks, enhance agility, and maintain uninterrupted supply of critical medical products.